How to Clean an RF Coaxial Adapter?

2025.10.31

2025.10.31

Industry News

Industry News

Content

1. Preparation Before Cleaning

Safety First: Ensure the RF coaxial adapter is disconnected from all cables and devices.

Work Environment: Select a clean, dust-free, and well-lit work surface.

Personal Protection: Wear anti-static gloves and finger cots to prevent sweat and oil from contaminating the interface and to prevent damage from electrostatic discharge.

Required Tools and Materials:

Anhydrous ethanol (99% purity or above) or isopropyl alcohol: This is the most commonly used cleaning solvent, volatile and leaving no residue. Do not use tap water, alcohol wipes (containing fragrances and additives), or ordinary cleaning agents.

Compressed air canister (or laboratory air source): For removing loose dust.

Medical cotton swabs: Ideally, those with tight, lint-resistant tips.

Cleanroom wipes/lens tissue: High-quality, lint-free.

Magnifying glass or microscope: For inspecting the cleanliness of the interface.

2. Cleaning Procedures for RF Coaxial Adapters

Step 1: Blowing Dust from the Outside

Hold the compressed air can upright and blow short streams of air onto the outside of the adapter and the connector end face.

Tip: Blow from the outside of the adapter toward the connector to "push" dust out, not "press" it in.

Step 2: Inspection and Preliminary Cleaning

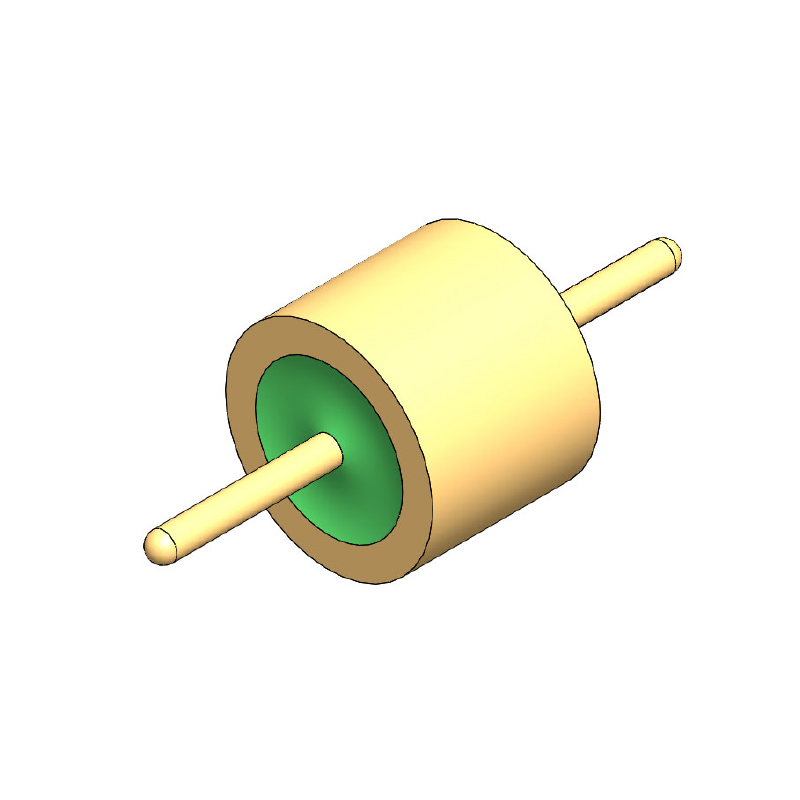

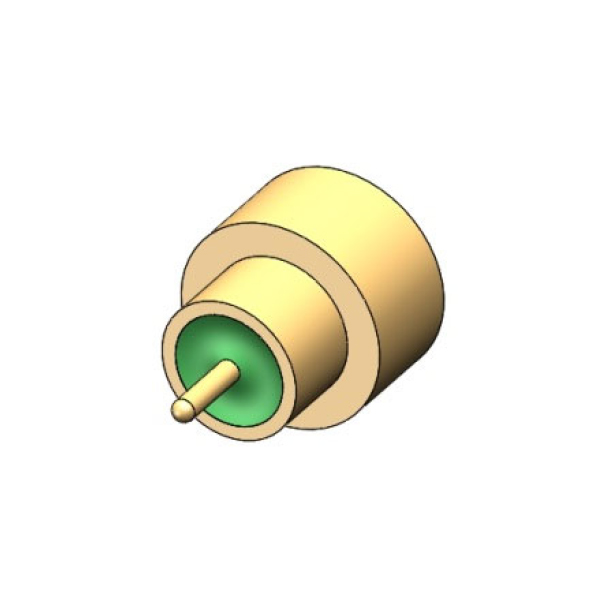

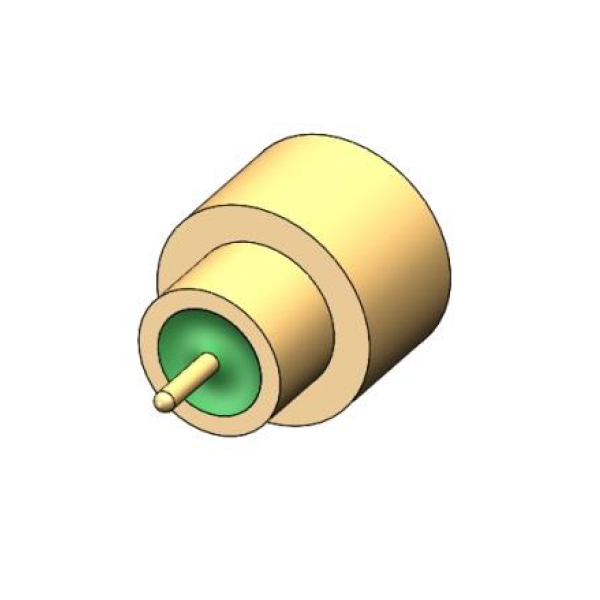

Carefully inspect the male (pin) and female (hole) connectors of the adapter under a magnifying glass.

Male connector: Inspect the center conductor for bends, oxidation, or contamination.

Female connector: Inspect the internal elastic contact for deformation, oxidation, and stains on the dielectric support surface.

If large foreign particles are found, use a compressed air can to remove them.

Step 3: Solvent Cleaning (Core Step)

Cleaning the Outer Conductor Threads:

Damp a dust-free cloth in an appropriate amount of anhydrous ethanol and gently wipe the threads of the outer conductor to remove grease and dirt. If the threads are severely dirty, use a soft-bristled brush (such as a brand new toothbrush) dipped in alcohol to gently scrub.

Cleaning the center conductor (the most critical part):

For male connectors (pins):

Dip a new cotton swab in an appropriate amount of anhydrous ethanol (not too much, just enough to avoid dripping).

Gently wrap the cotton swab around the center pin from different directions and wipe it in a circular motion along its axis. Avoid forcibly bending the center pin.

For female connectors (holes):

Dip a new cotton swab in an appropriate amount of anhydrous ethanol.

Gently insert the cotton swab tip into the female connector hole and gently wipe it in a circular motion. Ensure the cotton swab tip is the correct size and avoid applying excessive pressure to avoid damaging the internal elastic contact.

Cleaning the dielectric surface (such as PTFE):

The inside of the adapter typically has a white dielectric ring. Use a new cotton swab or a lint-free cloth dipped in alcohol and gently wipe the surface. The dielectric material is usually soft, so avoid scratching it.

Step 4: Drying

After cleaning, the solvent will evaporate quickly. However, to be sure, wait a minute or two for it to dry completely, or blow gently with a can of compressed air at room temperature and dry air to accelerate the drying process. Caution: Do not use a heat gun, as high temperatures may damage the media and seals.

3. Special Situation Handling

Oxidation/Corrosion: If the interface shows slight oxidation (blackening), try cleaning with a specialized electrical contact cleaner or more carefully with an alcohol swab. If oxidation is severe, the adapter may have deteriorated and should be replaced immediately.

Stubborn Stains: For stubborn stains, gently scrape with a plastic scraper or toothpick (use caution with wooden ones). However, this is highly risky and can easily scratch the metal surface, so it is not recommended for non-professionals.

Cleaning the Interior of the Interface Connector: For very delicate interfaces (such as 2.92mm and 1.85mm), it is recommended to use a specialized cleaning stick designed for specific interface dimensions to minimize damage.

4. Prohibitions

Do not use any abrasive tools, such as metal tweezers, blades, sandpaper, ordinary paper towels, or hard-bristle brushes, to directly scrape the contact surfaces. Do not use non-designated chemical solvents, such as acetone, board washer water, gasoline, and WD-40, as these may corrode plastic media or metal plating.

Do not use excessive force, especially when cleaning the center pin and female connector hole. Excessive force can cause physical deformation and permanent damage.

Do not connect before drying: Ensure the interface is completely dry before connecting to prevent short circuits.

5. Precautions

Capping when not in use: This is the most important and simplest maintenance method. Dust caps must be placed on both ends of unused adapters.

Proper Operation: When connecting, align the threads, tighten by hand, and then tighten with a wrench to the specified torque to avoid "gnawing" and mechanical damage.

Regular Inspection: Regularly inspect and clean inventory and frequently used adapters.

Request for a call today

English

English русский

русский