Why you need to clean hermetically sealed connectors?

2025.11.05

2025.11.05

Industry News

Industry News

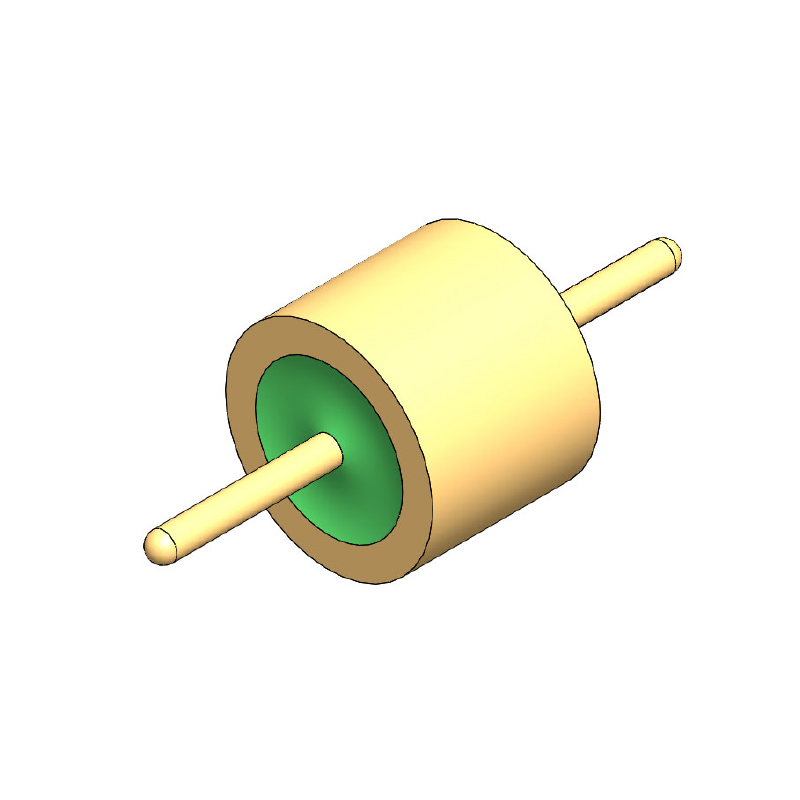

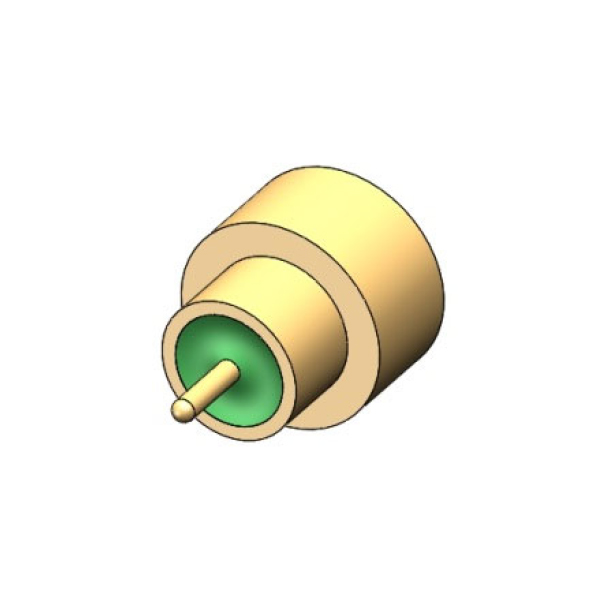

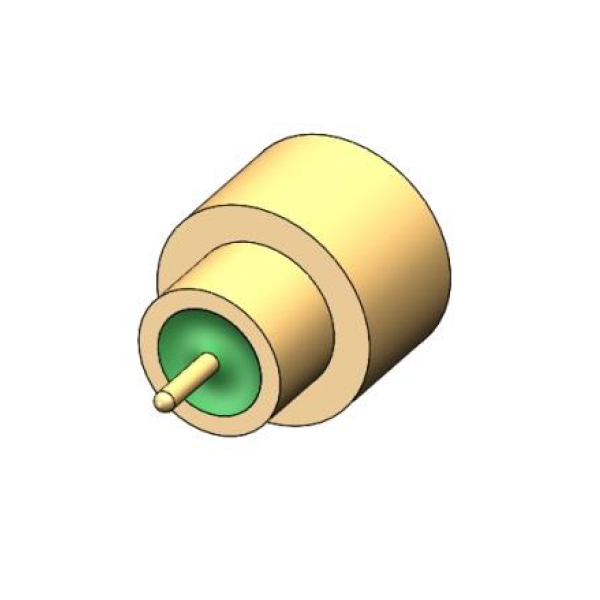

Hermetically sealed connectors are widely used in special environments such as aerospace, military equipment, medical equipment, automotive electronics and industrial control. Its core value lies in its ability to prevent the intrusion of moisture, gases and contaminants and protect internal precision circuits. However, tiny contamination at the connector interface is enough to defeat this solid layer of protection. Therefore, its cleaning is a precise process that must be strictly performed.

Content

1. Ensure electrical performance

Maintain stable contact resistance

Problem: The metal contacts between connector pins and receptacles are the channels through which signals and power are transmitted. Any non-conductive contaminants (such as dust, oil, fibers) will prevent direct metal-to-metal contact.

Consequences: causing contact resistance to increase, causing voltage drop and signal attenuation. For weak signals or high-frequency digital signals, this will directly cause data errors, increased bit error rates, or even complete signal interruption.

Protects against arcing and short circuits

Problem: Conductive contaminants (eg, metal shavings, certain types of carbonized dust) create "bridges" between adjacent pins.

Consequences: Under high-voltage applications, this can easily cause instantaneous arc discharge or permanent short circuit, which may burn expensive electronic components and bring down the entire system.

Ensure impedance matching (high frequency applications)

Problem: In high-frequency RF connectors, contaminants (such as moisture, oil films) with different dielectric constants from air can change the electromagnetic field distribution at the connection.

Consequences: Resulting in impedance mismatch, resulting in signal reflection, increased insertion loss, and serious degradation of communication quality and data transmission rate.

2. Ensure sealing integrity

Protective end seal

Problem: Most hermetically sealed connectors rely on elastomeric sealing rings such as silicone or fluoroelastomer to provide a physical seal. A hard contaminant (such as sand, metal shavings) presses against the sealing ring.

Consequences: When tightening connectors, the seals can be permanently crushed, cut, or deformed, creating leak paths that allow moisture and corrosive gases to enter.

Ensure smooth engagement and uniform force

Problem: Contaminants in the threaded or bayonet connection mechanism can prevent the connector from fully and smoothly mating into place.

Consequences: As a result, the hermetically sealed connector cannot reach the specified torque value, leaving the entire connection in a "virtual connection" state. Insufficient sealing pressure will also cause leakage.

3. Maintain physical and mechanical properties

Prevent corrosion and wear

Problem: Hygroscopic contaminants (such as salt, dust) will absorb moisture in the air and form electrolyte on the surface of the pins.

Consequences: accelerated electrochemical corrosion, damage to precious metal coatings (such as gold, silver), resulting in a surge in resistance. Hard contaminants will also wear the delicate gold plating layer during the plugging and unplugging process, affecting the connection life.

Achieve correct plugging and locking

Problem: Dirt or dried grease can increase connector mating and unmating forces.

Consequences: It makes it difficult for the hermetically sealed connector to be fully inserted, or it cannot be pulled out smoothly when separation is required, affecting maintenance efficiency and even causing danger in an emergency.

4. How to properly clean hermetically sealed connectors?

Use professional tools and solvents:

Tools: Lint-free cloth (such as chamois cloth), special cotton swabs, high-pressure clean dry air or nitrogen.

Solvent: Electronic grade, high purity isopropyl alcohol or special contactor cleaner must be used. Do not use tap water, alcohol or detergents containing grease.

Strictly follow the operating procedures:

Purge: First use an air gun to blow away loose particles.

Wipe: Use a lint-free cloth or cotton swab dipped in an appropriate amount of solvent, and wipe the contact surface in one direction to avoid the spread of contaminants caused by wiping back and forth.

Drying: Make sure the solvent has completely evaporated before making the connection.

Environment and protection:

Operate in a highly clean environment (such as a clean workbench).

Operators need to wear finger cots or gloves to prevent hand oil contamination.

Request for a call today

English

English русский

русский