Do RF connectors need cleaning?

2025.10.24

2025.10.24

Industry News

Industry News

Content

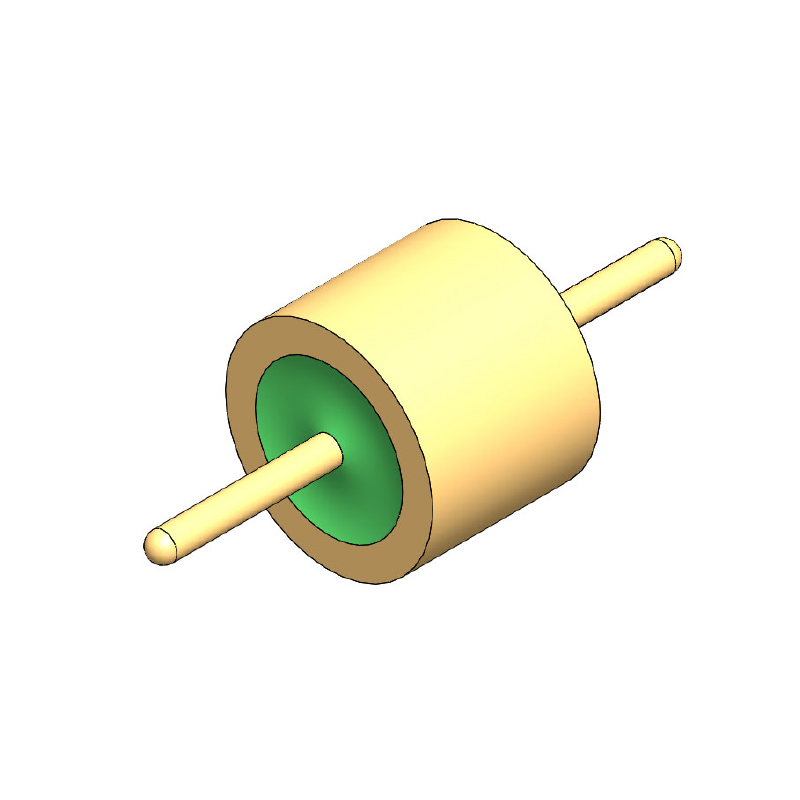

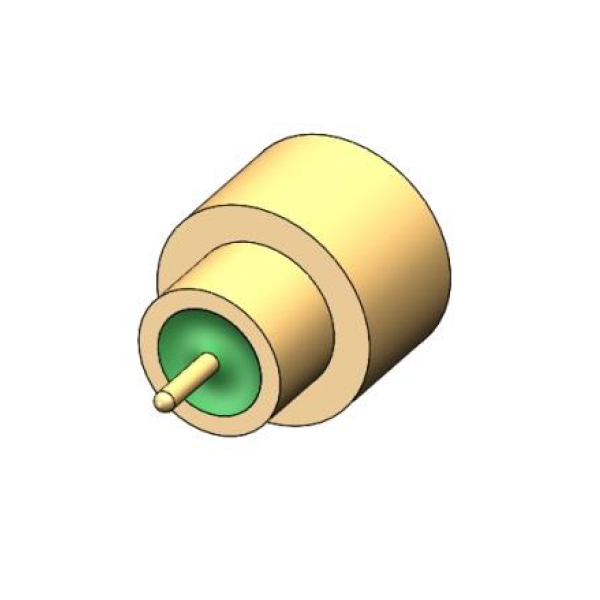

1. Why Do RF Connectors Need Cleaning?

Impedance Matching: RF connectors are designed for precise impedances (such as 50Ω or 75Ω). Dirt, dust, or oxidation can alter the electrical characteristics of the contact points, leading to impedance mismatch, signal reflections, increased return loss, and reduced transmission efficiency.

Insertion Loss: Contaminants increase signal attenuation, resulting in energy loss and manifesting as a decrease in signal strength.

Preventing Intermittent Faults and Signal Distortion:

Small dust or metal debris can cause poor connections, resulting in "clicking" sounds, intermittent signals, or phase noise—problems that are difficult to diagnose.

Protecting Device Interfaces:

Hard contaminants can scratch the connector's delicate gold plating during connection and disconnection. Once the gold plating is damaged, the underlying base metal (such as copper or brass) rapidly oxidizes when exposed to air, permanently degrading performance.

Oxidation (such as verdigris) can significantly increase contact resistance.

2. How to clean the RF connector correctly?

Cleaning the RF connector requires meticulous and correct methods. Rough cleaning is more harmful than not cleaning it.

(1). Required tools (professional tools are recommended)

Anhydrous ethanol (purity above 99%) or isopropyl alcohol: This is the most commonly used and safe solvent, which is volatile and leaves no residue.

Dust-free cloth/wiping paper: Special lens paper or fiber dust-free cloth. It is strictly forbidden to use paper towels or ordinary cloth to avoid leaving fiber scraps.

Compressed air can or air blower: Used to blow away large particles of dust.

Soft brush: Natural camel hair brush or anti-static brush, used to gently sweep away dust.

Cotton swab: Used to clean hard-to-reach corners.

(2). Cleaning steps

Disconnection: Before cleaning, make sure the device is completely powered off. Carefully unscrew the connector to avoid pulling the cable.

Visual inspection: First, carefully inspect the male and female connectors for physical damage (such as indentations, dents), bent pins, or severe oxidation.

Blowing: Use a compressed air can or air blower to blow away loose dust and particles from the center outward. Note: When using a compressed air can, keep the can upright and spray briefly to prevent condensation from spraying out.

Brushing: Use a soft-bristled brush to gently sweep away stubborn particles.

(3) Solvent cleaning (critical step):

Pour a small amount of anhydrous ethanol or isopropyl alcohol onto a dust-free cloth or cotton swab (never pour solvent directly onto the connector).

For male connectors, wipe the outer conductor and threads along the thread direction with a dust-free cloth dipped in solvent, then wipe dry with a dry dust-free cloth.

For the center pin, use a cotton swab dipped in solvent to gently wipe from the root to the tip in one direction.

For female connectors, gently insert a cotton swab dipped in solvent into the hole and rotate it to wipe the inner wall conductor.

Principle: Use the "wet first, dry second" method to ensure that all solvent and dirt are completely removed, leaving no residue.

Dry thoroughly: Wait several tens of seconds to ensure that all solvent has evaporated. The connector must be completely dry.

Reconnecting: Carefully align the connector and initially tighten by hand to ensure that the threads are not cross-threaded. Finally, tighten to the specified torque using a torque wrench. Do not overtighten with a standard wrench, as this will damage the threads and seals.

3. Cleaning Frequency and Precautions

When to clean:

Before each connection, if contamination is detected on the connector.

When system performance is abnormal (such as increased insertion loss or poor standing wave ratio).

After use in harsh environments (such as the field or factory floor).

Perform preventive maintenance according to a scheduled schedule (such as quarterly or semi-annual).

Important Dos and Don'ts:

Do not use abrasive materials such as sandpaper, metal brushes, and erasers, as they will damage the plating. Do not use non-designated solvents such as acetone, board-washing water, tap water, or oil-based cleaners, as these can corrode plastic components or leave insulating residue.

Avoid touching contact surfaces: Hand oil and sweat are common sources of contamination.

Request for a call today

English

English русский

русский