How to Extend the Life of RF Coaxial Connectors?

2025.10.17

2025.10.17

Industry News

Industry News

Although RF connectors are strong, their precision interfaces are very fragile. Improper operation is the main reason for performance degradation and shortened life. Following the following guidelines can extend their service life:

Content

1. Standardize operation and avoid violence

(1) Use a torque wrench to connect

Tightening the connector by hand can easily lead to excessive or insufficient force.

Overtightening: It can cause thread stripping, shell deformation, center conductor depression, and even damage to the dielectric material. This damage is usually irreversible.

Overloosening: It can cause poor contact, impedance discontinuity, signal reflection, and easy loosening due to vibration, and may also allow dust and moisture to penetrate.

Operation: Strictly follow the torque value specified for the connector type (such as SMA is usually 0.9 N·m, N type is 1.4-2.0 N·m), tighten with a torque wrench, and hear a "click".

(2) Align the threads to avoid "wrong teeth"

Before connecting, ensure that the threads of the male and female heads are completely aligned. Operation: First, gently screw the connector in by hand to ensure that the entire process is smooth and without resistance. If it feels stuck, withdraw it immediately and realign it. Do not force it in with a wrench. Forcing it in will cause it to "snag" and damage the threads.

(3) Keep the connector axes aligned

When connecting, ensure that the axes of the two connectors are in a straight line to avoid angled connections or lateral stress.

Operation: For cable assemblies, hold the cable and connector roots with your hands when connecting, keep them straight when inserting and tightening, and prevent stress on the connector roots.

2. Daily use and maintenance

(1) Keep clean

Dust and pollutants: Dust, oil, metal debris, etc. can cause poor contact, increase insertion loss and generate intermodulation distortion.

Operation: Cover the dust cap at all times: When not in use, immediately cover the dust cap for the male and female connectors.

Use professional cleaning tools: Use dust-free cloths, special cotton swabs and high-purity (>99.9%) anhydrous ethanol or isopropyl alcohol for cleaning. Avoid using ordinary cotton swabs containing cotton wool or low-quality alcohol.

Cleaning method: First, gently blow away the surface dust, then use a cotton swab dipped in detergent to gently wipe the center pin and external threads, and finally wipe dry with a dry cotton swab.

(2) Avoid frequent plugging and unplugging

Each RF connector has its mechanical life (usually 500-1000 plugging and unplugging times). After exceeding the number of times, the elasticity of the contact spring will decrease, resulting in performance degradation.

Operation: In the test system, try to use a switch matrix to switch the signal path to reduce the number of manual plugging and unplugging.

3. Storage and Environmental Management

Store connectors in a dry, clean environment free of corrosive gases.

Use the original dust cap or a dedicated protective box for storage to prevent contact.

Avoid use in environments with excessive humidity, salt spray, or chemical vapors, as these can accelerate oxidation and corrosion of the metal contacts.

4. Regular Inspection and Identification of Damage Signs

Making a habit of inspection before use can help identify potential problems and prevent damage to the mating device port.

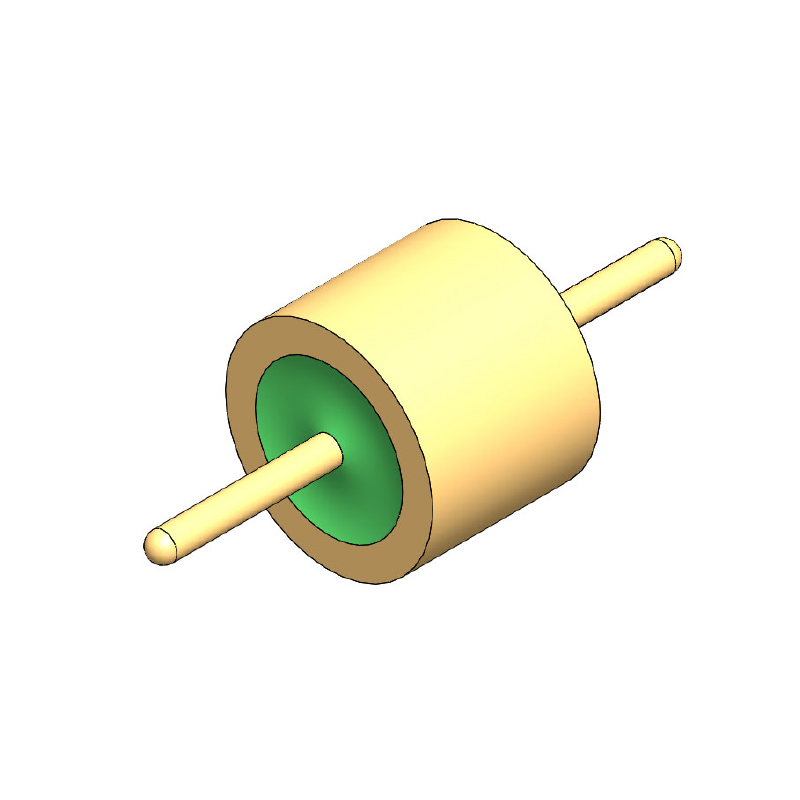

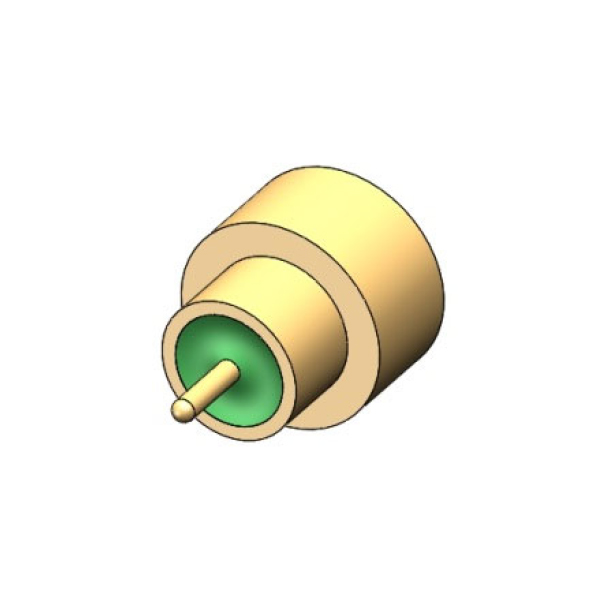

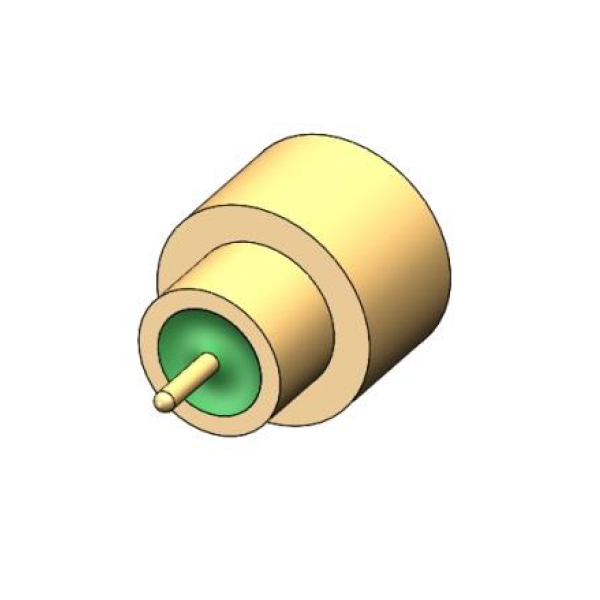

Inspect the male connector:

Center pin: Is it straight and not bent? Is there any denting, retraction, or excessive wear?

Dielectric material: Is the surface flat, clean, and free of dents or burn marks?

Threads: Are they clear, free of wear, and burrs?

Inspect the female connector:

Contact spring (spring): Is it round and flexible? Has it been deformed or opened due to excessive insertion and removal?

Dielectric material: Inspect the same way as for the male connector.

Threads: Inspect the same way as for the male connector.

If any of the above signs of damage are found, stop using it immediately and replace the connector. Using a damaged connector may ruin the interface of an expensive instrument.

Request for a call today

English

English русский

русский