What is Super Low-Loss Flexible Cable Assembly?

2025.10.11

2025.10.11

Industry News

Industry News

Super Low-Loss Flexible Cable Assembly is a high-performance cable system designed specifically for high-frequency signal transmission. It features extremely low signal loss and excellent bending performance, making it widely used in high-precision applications such as 5G communications, aerospace, and medical equipment. Its core feature is its specialized materials and structural design, which minimize signal attenuation and interference while maintaining flexibility.

Content

1. Features of Ultra-Low-Loss Flexible Cable Assembly

Ultra-Low Transmission Loss: ≤0.5 dB/m at high frequencies (such as the millimeter wave band) (compared to >1 dB/m for standard cables). This is achieved through materials with low dielectric constant (Dk) and low loss tangent (Df), such as PTFE/expanded polyethylene foam.

Highly Flexible Design: Reliable bending (bend radius ≤ 5 times the outer diameter), making it suitable for dynamic cabling scenarios (such as robotic arms and wearable devices).

Stable Impedance Matching: Tight impedance tolerance (e.g., 50Ω ± 1Ω) reduces signal reflections (VSWR < 1.2). Environmental adaptability: High-temperature resistance (-65°C to 200°C), radiation resistance (aerospace-grade), and corrosion resistance (medical/marine applications).

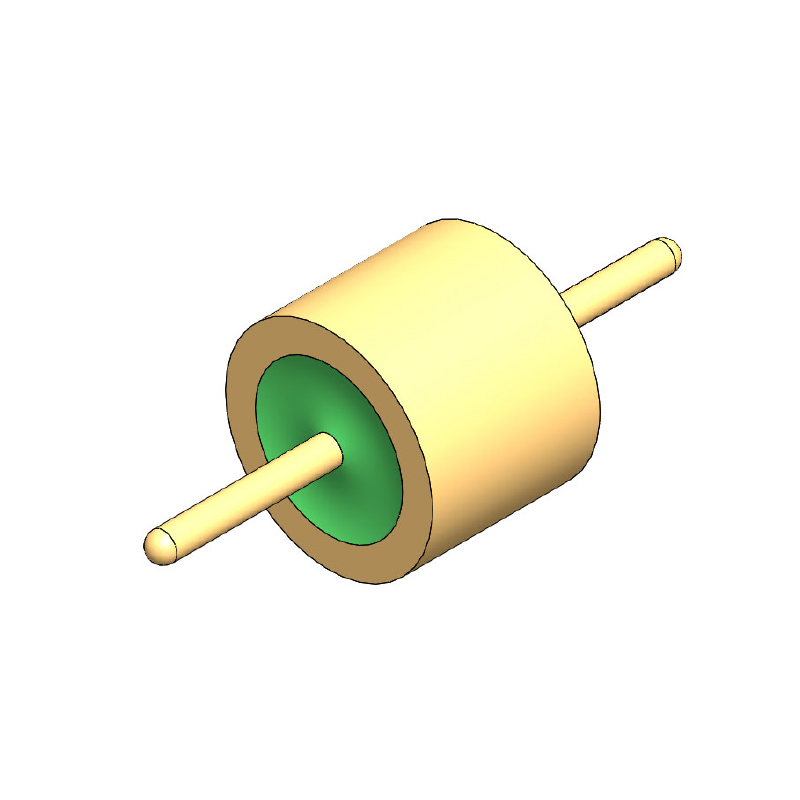

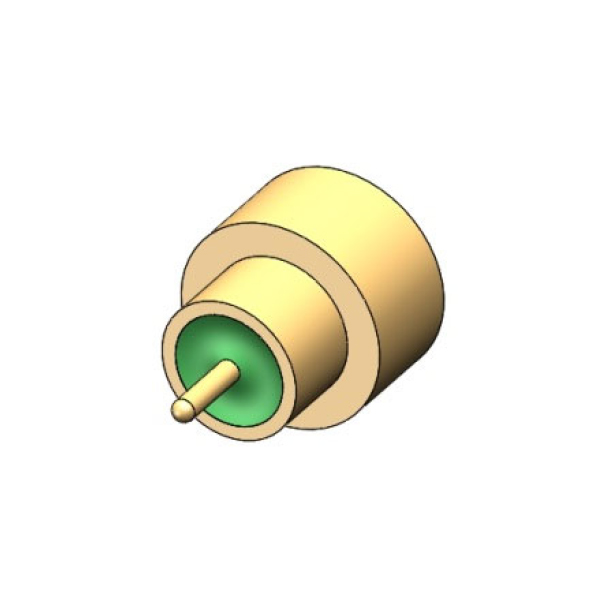

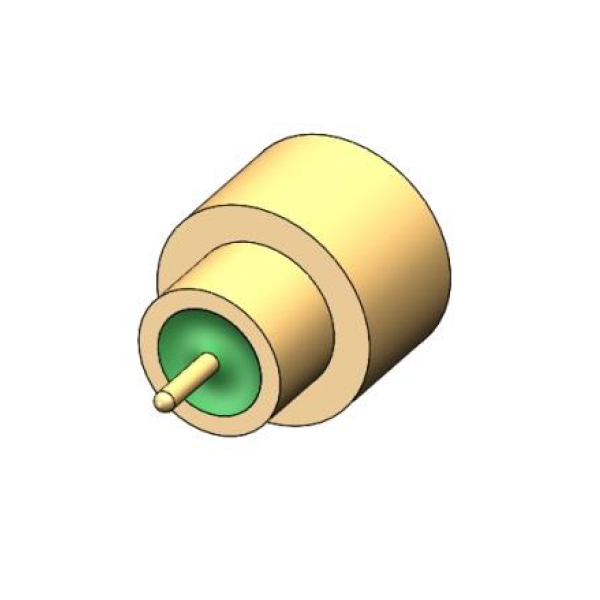

2. Key structural design

| Components | Material/Process | Function |

| Conductor | High-purity silver-plated copper wire/copper-clad aluminum | Reduced resistance and skin-effect loss |

| Insulation | Expanded PTFE, FEP, or PP | Reduced dielectric loss and improved flexibility |

| Shielding | Double-layer braided shield (silver-plated copper wire + aluminum foil) | Electromagnetic interference (EMI) protection |

| Jacket | Thermoplastic polyurethane (TPU)/Silicone | Abrasion-resistant and flex-resistant |

3. Maintenance of Ultra-Low-Loss Flexible Cable Assembly

(1) Taboos

Risk of Mechanical Damage

Prohibition: The bending radius is less than 5 times the outer diameter of the cable (for example, if the cable diameter is 6mm, the minimum bending radius must be ≥30mm). Twisting, knotting or sharp folding are prohibited (which may cause the internal shielding layer to break).

Correct operation: For dynamic applications (for example, robotic arms), please use a dedicated cable drag chain.

(2) Environmental Limitations

Temperature: It is strictly forbidden to exceed the nominal range (for example, -65℃~200℃). High temperature may melt the insulation layer (for example, FEP material).

Chemical contact: Avoid contact with strong acids, strong alkalis or organic solvents (for example, acetone will corrode PTFE insulation layer).

(3) Installation Taboos

Do not clamp the cable directly with pliers (strain relief connectors must be used). Do not overstretch (the pulling force should be greater than the nominal tensile strength of the cable, for example, 50N).

Correct operation: Use cable ties to loosen the cable when fixing to avoid local pressure.

Request for a call today

English

English русский

русский