-

Proper Installation of a Coaxial Connector Ensures Maximum Signal Performance Installing a Coaxial Connector correctly prevents signal loss, interference, and connection failure. A poorly installed connector can reduce signal strength by 20–50%, cause intermittent connectivity, and even damage connected equipment. By ...

READ MORE -

What is an RF Coaxial Connector and Why is it Important? An RF coaxial connector is a crucial component used to transmit radio frequency (RF) signals between devices. These connectors ensure reliable and secure connections for high-frequency signals, which are essential in telecommunications, broadcasting, and network...

READ MORE -

What Are Hermetically Sealed Connectors? Hermetically sealed connectors are specialized connectors that are designed to protect sensitive electronic components from environmental elements like moisture, dust, and corrosive gases. The term "hermetically sealed" refers to the connector’s ability to create an airtight se...

READ MORE

RF coaxial connectors are specialized connectors used to transmit high-frequency electrical signals. As key components of modern electronic systems, they play an irreplaceable role in communications, military, aerospace, and other fields. Ningbo Hansen Communication Technology Co., Ltd. is a Chinese RF coaxial connector manufacturer and wholesaler of 50-ohm and 75-ohm RF coaxial connectors.

RF coaxial connectors are based on electromagnetic field transmission theory and achieve low-loss transmission of high-frequency signals through a precisely designed coaxial structure. Their core principle is to maintain a consistent characteristic impedance (typically 50Ω or 75Ω), allowing electromagnetic waves to propagate as transverse electromagnetic waves (TEM mode). When the connectors are mated, the inner and outer conductors form a continuous transmission path. The elastic contact design and surface treatment ensure minimal contact resistance (typically <1mΩ).

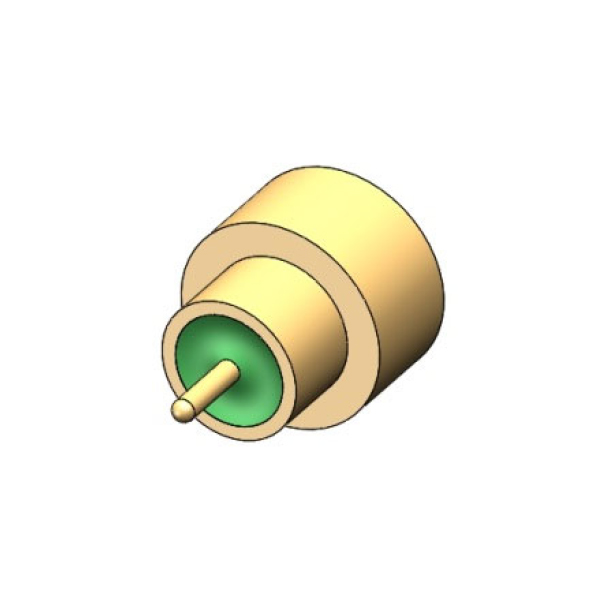

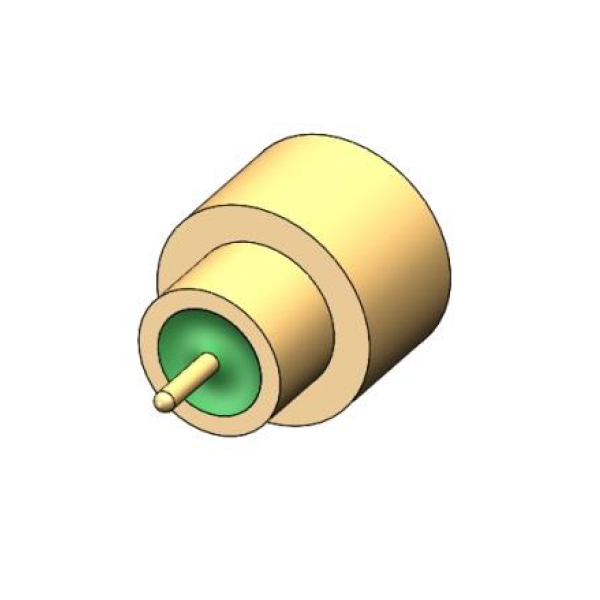

A standard RF coaxial connector consists of three core components:

1) Center Conductor: Made of materials such as beryllium copper alloy, with a gold-plated surface.

2) Dielectric Support: Commonly made of low-dielectric-loss materials such as PTFE and ceramic.

3) Outer Conductor: Precision-machined to ensure mechanical strength and shielding effectiveness.

Proper installation of RF coaxial connectors is critical to ensuring system signal transmission quality and requires strict adherence to scientific operating procedures and technical requirements. Thorough preparation is essential before installation, including checking the accuracy of the torque wrench, creating an anti-static work environment, and rigorously inspecting the connector to ensure end-face scratches do not exceed 0.05mm and contact resistance is less than 1mΩ. The installation environment should be maintained in a clean room with a temperature of 15-30°C and a humidity of no more than 60% RH. The work surface must meet anti-static standards.

The installation process begins with meticulous end-face preparation using a three-step cleaning method: first, use air to remove surface particles, then wipe with a non-woven cloth soaked in anhydrous ethanol in a single direction, and finally allow to dry for 2 minutes. Professional testing equipment is required for alignment and calibration to ensure that the axial deviation angle is controlled within ±0.5° and the radial offset does not exceed 0.02mm. Tightening requires staged force application, starting with pre-tightening and then gradually increasing to the specified torque value. Torque requirements vary for different connector types. For example, the standard torque for SMA connectors is 0.23N·m±0.02, while that for N connectors is 1.36N·m±0.05. After installation, comprehensive performance verification must be conducted, including insertion loss testing, voltage standing wave ratio testing, and third-order intermodulation testing. Mechanical reliability must also be verified through axial tension testing and vibration testing.

Request for a call today

English

English русский

русский