-

Proper Installation of a Coaxial Connector Ensures Maximum Signal Performance Installing a Coaxial Connector correctly prevents signal loss, interference, and connection failure. A poorly installed connector can reduce signal strength by 20–50%, cause intermittent connectivity, and even damage connected equipment. By ...

READ MORE -

What is an RF Coaxial Connector and Why is it Important? An RF coaxial connector is a crucial component used to transmit radio frequency (RF) signals between devices. These connectors ensure reliable and secure connections for high-frequency signals, which are essential in telecommunications, broadcasting, and network...

READ MORE -

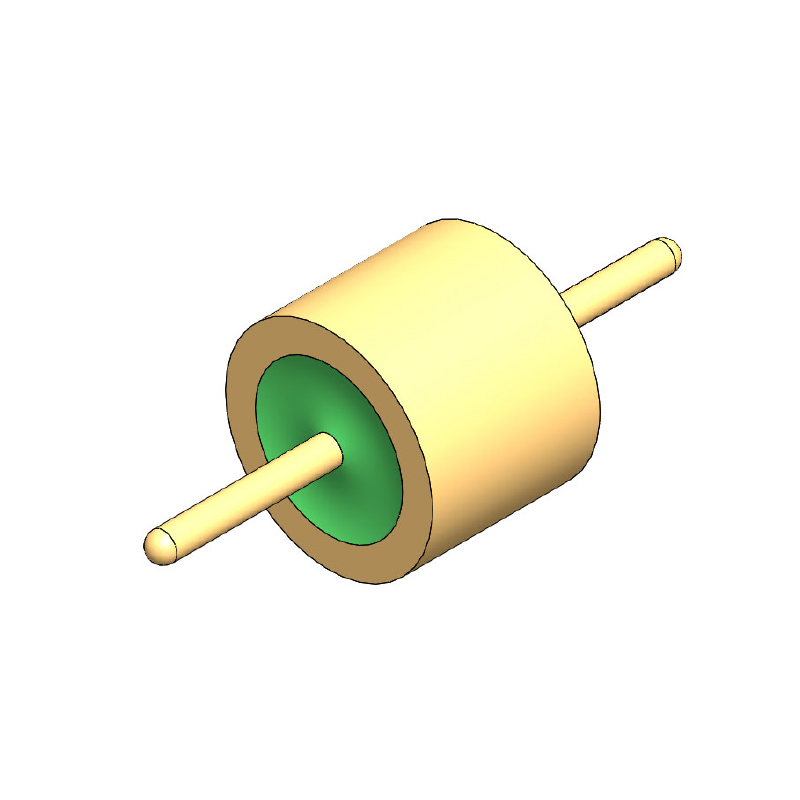

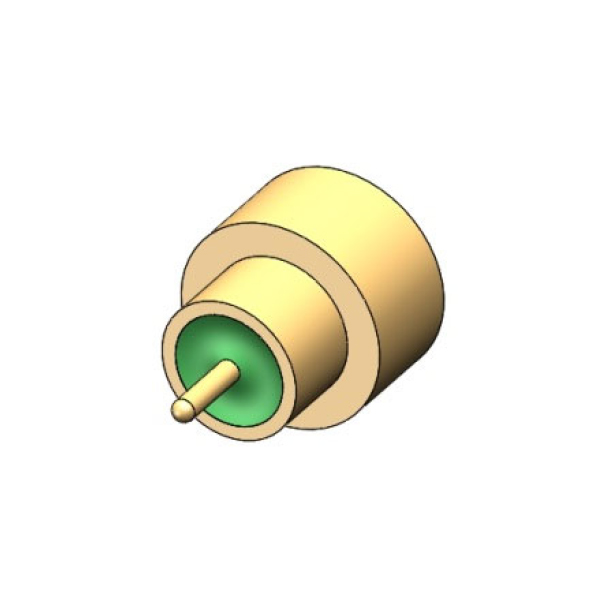

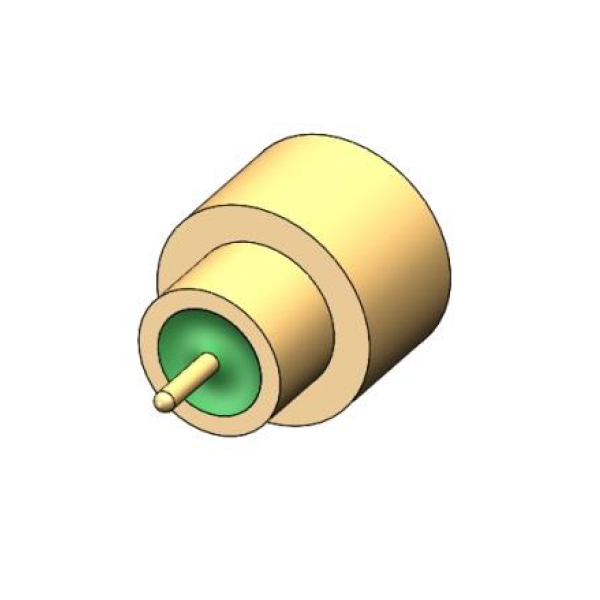

What Are Hermetically Sealed Connectors? Hermetically sealed connectors are specialized connectors that are designed to protect sensitive electronic components from environmental elements like moisture, dust, and corrosive gases. The term "hermetically sealed" refers to the connector’s ability to create an airtight se...

READ MORE

Hermetic connectors are specialized connection devices used to transmit power, signals, or fluids while effectively preventing the leakage or intrusion of gases, liquids, or contaminants through the interface. Through precise structural design and material selection, hermetic connectors create a reliable sealing barrier at the interface between plug and receptacle, and between housing and cable, ensuring stable operation in harsh environments such as moisture, high pressure, corrosive environments, or vacuum. Hermetic sealing is a sealing structure or technology that effectively isolates air, gas, or other gaseous media, ensuring that the performance of a sealed container or system is not affected by the ingress of external air or gas during operation. Hermetic sealing is typically used in applications that require maintaining a stable internal environment to prevent gas leakage or contamination.

Sealed connectors are widely used in industrial, automotive, aerospace, and medical equipment. Their core function is to ensure a stable electrical connection while protecting against environmental factors such as water, dust, and chemicals. However, in actual use, sealed connectors can still experience various failures due to design, materials, installation, or environmental factors, affecting the normal operation of the equipment. Understanding common sealed connector failures and their solutions, combined with preventive maintenance recommendations, can help users improve connector reliability and service life. Ningbo Hansen Communication Technology Co., Ltd. is a manufacturer specializing in the production, processing, and trading of communications components, with over 30 years of experience in RF coaxial connectors, adapters, and cable assemblies.

One of the most common failures of sealed connectors is seal failure, resulting in liquid or gas leakage. Seal failure is typically caused by aging, deformation, or damage to the seal ring, such as hardening, cracking, or permanent deformation of the rubber material after long-term use. Improper installation is also a major cause, such as improper seal alignment and insufficient or excessive compression, which can compromise the seal. Corrosion or thread wear on the connector housing can also impair the seal, especially in humid, salt-spray, or chemically aggressive environments. Extreme temperature and pressure fluctuations can also cause the seal material to expand or contract, reducing sealing performance. Solutions to this problem include selecting high-performance sealing materials (such as fluoroelastomers, silicone rubber, and other chemically and high-temperature resistant materials), strictly adhering to installation specifications (such as using a torque wrench to ensure uniform compression), and optimizing the seal structure design (such as using dual seals or incorporating potting compounds for enhanced protection). For corrosive environments, corrosion-resistant housing materials such as stainless steel and nickel-plated alloys should be preferred.

Request for a call today

English

English русский

русский