What are the most common mistakes to make when installing SMA connectors?

2025.11.19

2025.11.19

Industry News

Industry News

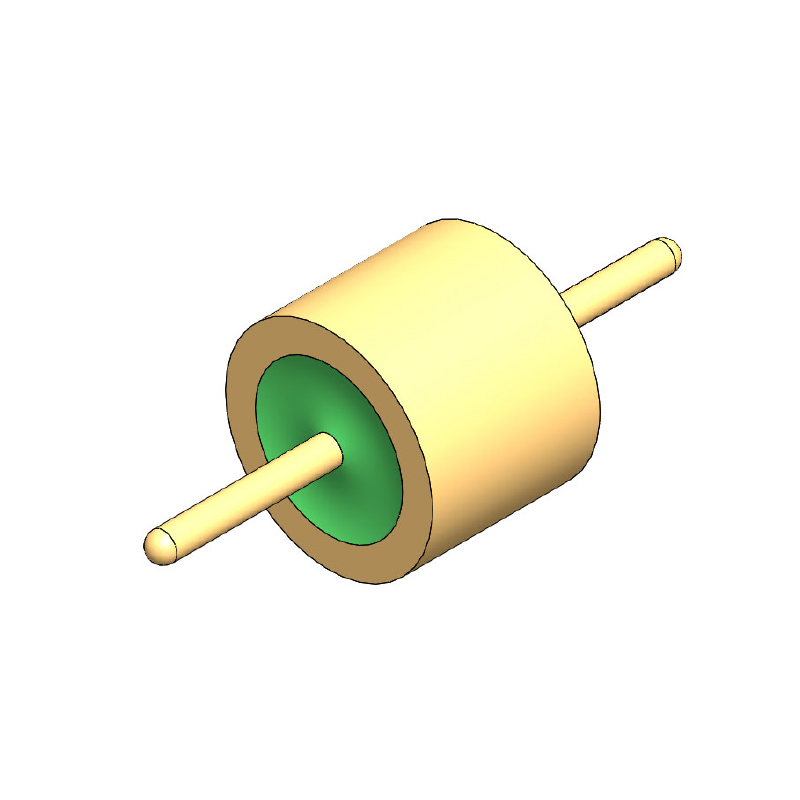

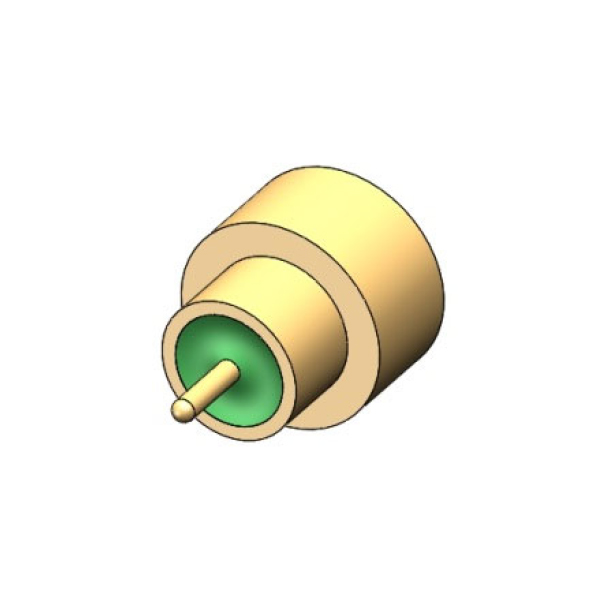

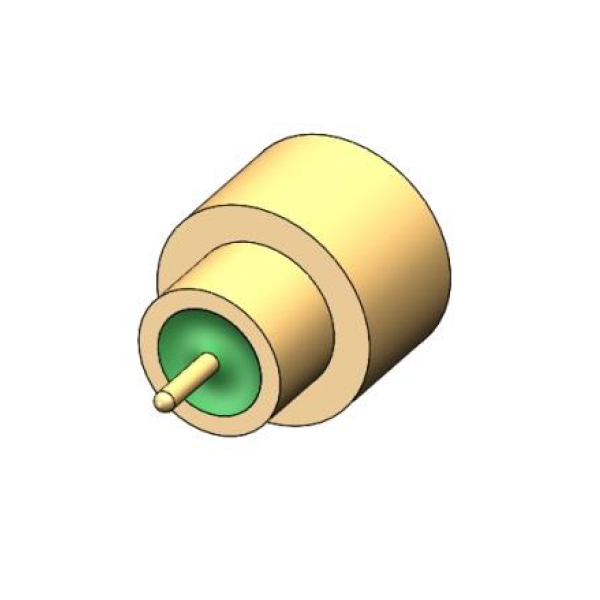

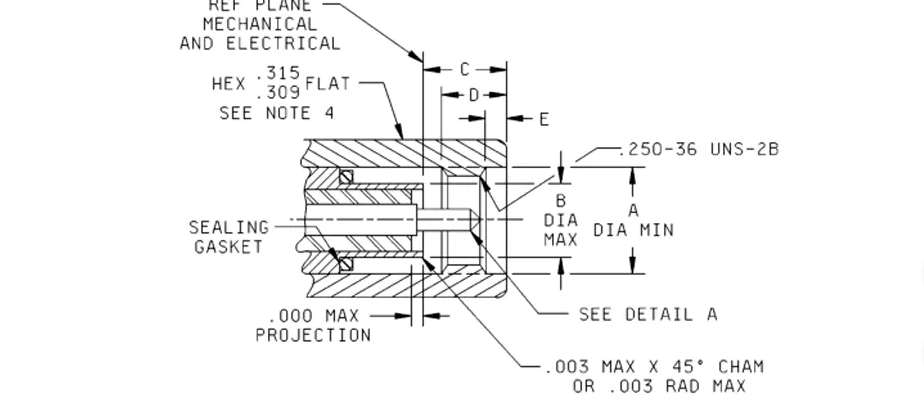

SMA connectors are one of the most common and widely used coaxial connectors in RF applications, widely used in communication equipment, microwave systems, antennas, test instruments, GPS, radar, and other high-frequency systems. Although the structure of an SMA connector seems simple, even a small mistake during installation or connection can lead to signal attenuation, increased VSWR, poor contact, and even equipment malfunction. Therefore, proper installation of SMA connectors is crucial.

1. Incorrect Tightening Torque

Many users fall into a common misconception when installing SMA connectors: either they just tighten it casually, or they tighten it with brute force until it's "very tight." Both approaches will cause problems.

If it's not tightened enough, poor contact and unstable connection will occur, making the signal susceptible to interference. Especially in vibration environments, the SMA head will gradually loosen, leading to increased reflections and even signal interruption. If it's overtightened, it will damage the inner core, deform the threads, and damage the dielectric structure, resulting in irreversible performance degradation.

The correct procedure is to use a torque wrench to tighten it to a standard torque of approximately 0.8 N·m. This ensures a secure contact while preventing structural damage, making it an essential tool for professional RF installation.

2. Misalignment of the center conductor

SMA connectors are precision RF connectors with extremely small center conductors (pins or sockets). Misalignment during mating and forced insertion can easily cause pin bending and socket deformation. This type of damage is often irreparable and may not be visible to the naked eye, but it directly leads to:

Increased VSWR

Increased signal loss

Unstable contact

Difficulty in insertion and removal

Signal lifespan significantly shortened

Especially in test equipment or high-frequency systems, this damage degrades the entire link performance and is difficult to troubleshoot.

The correct procedure is to align the conductor carefully, insert it gently, and then secure it with a torque wrench. Never use brute force.

3. Hand-tightening introduces metal debris and oxides into the interface

Many engineers habitually tighten SMA connectors by hand, especially during frequent testing. This not only results in insufficient torque but also easily introduces contaminants such as dust, metal debris, and skin oils. These tiny particles can increase contact resistance and even damage the gold plating, leading to increased signal attenuation.

In high-frequency connectors, even the smallest impurities can cause performance fluctuations. Therefore, it is essential to:

Do not tighten by hand (only lightly tighten during initial positioning);

Clean the connection surfaces with a lint-free cloth or alcohol swab before installation;

Avoid touching the conductive surfaces with bare hands;

Good cleaning habits can significantly extend the connector's lifespan.

4. Mixing SMA Male and Female Connector Types

SMA connector interfaces are very similar in appearance to other RF interfaces, such as RP-SMA, SMB, SMC, and N-type. Many people judge based on appearance, resulting in the forced connection of incompatible interfaces, which can cause:

Damaged threads

Broken center pins

Deformed inner holes

Complete performance failure

SMA and RP-SMA (reverse polarity SMA) are especially easily confused. They look similar but have different internal structures. Forcing a connection not only prevents signal transmission but may also damage the device interface.

Before connecting, always confirm:

Is it a standard SMA connector?

Is the connector type correct?

Is it compatible with the device port?

Does it meet frequency requirements (there is a difference between standard and precision SMA connectors)?

Avoid damaging expensive equipment due to improper operation.

5. Excessive bending of the connecting cable causes impedance discontinuities

Many problems when installing SMA connectors are not actually at the connector itself, but rather due to improper cable bending during installation. Coaxial cables are very sensitive to bending radii. If bent too sharply, it will lead to:

Impedance discontinuities

Increased signal reflection

Increased cable loss

Instantaneous test results.

These problems are particularly noticeable in high-frequency (above 6GHz) applications.

Recommended guidelines:

Bending radius ≥ 5 times the cable diameter

Avoid bending near the connection point

Avoid applying tension or torsion to the cable.

This will maintain stable transmission performance.

6. Frequent mating and unmating causes wear

The theoretical lifespan of an SMA connector is typically around 500 mating and unmating cycles, but many testing environments may involve dozens of mating and unmating cycles per day. Prolonged repeated use can cause: wear of the gold plating; increased contact impedance; blade deformation; and loosening of the center conductor, affecting signal stability and even increasing errors.

Solutions include: using a protective adapter (SMA saver) in high-frequency testing environments; regularly replacing test cables; and monitoring changes in connector contact impedance. This can significantly extend the lifespan of interfaces on valuable instruments.

While installing SMA connectors is simple, every detail directly impacts signal quality. Following standard procedures and using the correct tools ensures stable connections, reliable performance, and a longer equipment lifespan.

Request for a call today

English

English русский

русский