What is the function of a hermetically sealed connector?

2025.09.11

2025.09.11

Industry News

Industry News

1. What is a hermetically sealed connector?

A hermetically sealed connector is a specialized connection device that transmits power, signals, or fluids while effectively preventing the leakage or intrusion of gases, liquids, or contaminants through the interface. Through precise structural design and material selection, it forms a reliable sealing barrier at joints, such as between plugs and sockets, or between housings and cables, ensuring stable operation in harsh environments such as those characterized by humidity, high pressure, corrosive environments, or vacuum. A hermetic seal is a sealing structure or technology that effectively isolates air, gas, or other gaseous media, ensuring that the performance of a sealed container or system is not affected by the ingress of external air or gas during operation. Hermetic seals are typically used in applications where maintaining a stable internal environment to prevent gas leakage or contamination is crucial.

The core of a hermetic connector lies in its hermetic sealing capability. This capability is achieved by using techniques such as rubber seals, metal welding, glass sintering, or potting to block the penetration paths of gas molecules at a microscopic level. For example, high-voltage connectors in automotive batteries use multi-layer silicone seals to protect against water and dust, while fuel valves on spacecraft rely on a molecular-level fusion of metal and glass to maintain the vacuum of space. This sealing not only prevents the intrusion of external water vapor and dust, but also prevents the leakage of internal media (such as flammable gases and corrosive liquids), thereby ensuring system safety and extending component life.

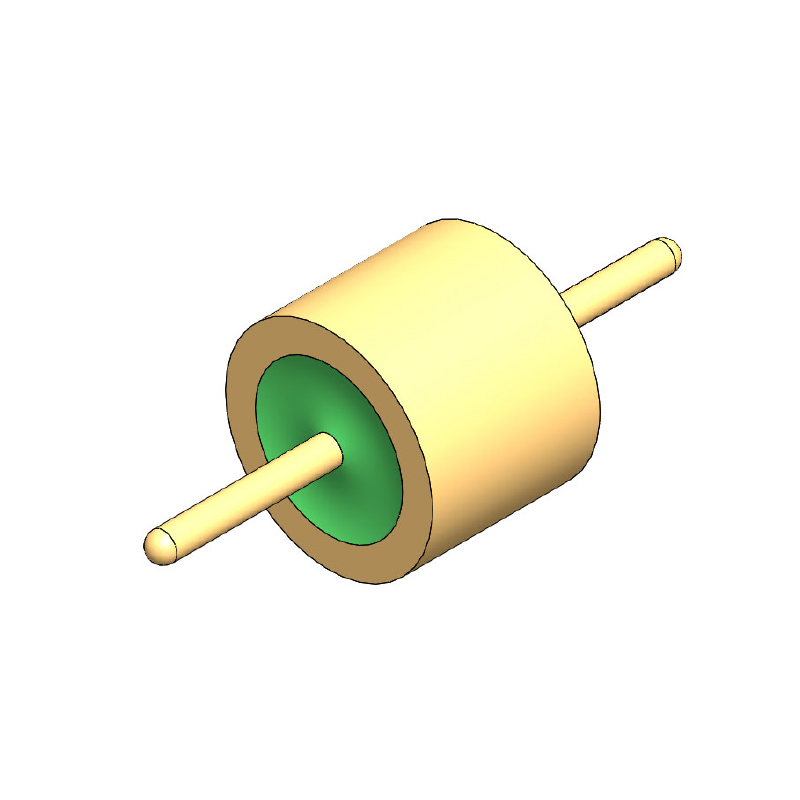

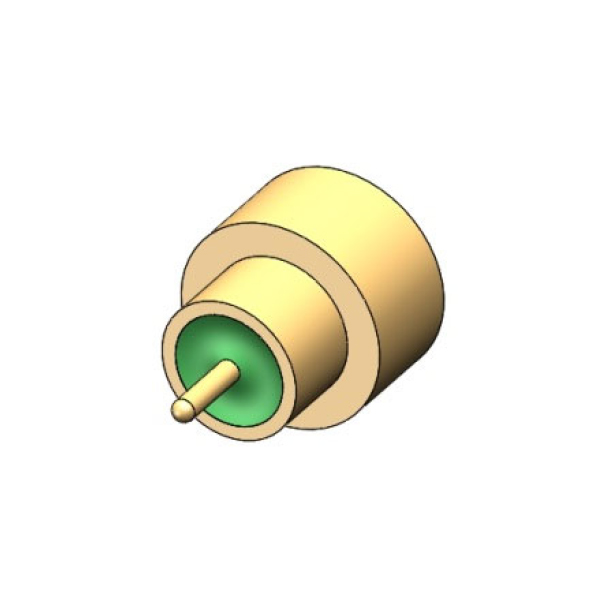

Basic components of a sealed connector

Connecting components: pins, sockets, and housing (transmitting signals/power/fluids).

Sealing components: sealing rings, potting compound, and solder layers (providing media isolation).

Core functions

Leak prevention: Prevents internal gas/liquid leakage (e.g., gas sensors and hydraulic systems).

Intrusion prevention: Isolates external moisture, dust, and corrosive gases (e.g., outdoor electronics and chemical equipment).

Pressure maintenance: Maintains a stable vacuum or high-pressure environment (e.g., spacecraft and refrigeration pipelines).

Hermetically sealed connectors are a key feature of hermetically sealed connectors. Hermetically sealed connectors are categorized into two types: static sealing and dynamic sealing:

| Sealing type | Implementation method | Technical features | Typical applications |

| Static sealing | Rubber O-rings, metal gaskets | Rely on compression deformation to fill gaps, low cost | Automotive wiring harnesses, home appliance control panels |

| Dynamic sealing | Rotary shaft seals, bellows seals | Allows relative motion while maintaining a seal, complex structure | Industrial robot joints, hydraulic rotary joints |

| Molecular-level sealing | Metal-glass sintering, laser welding | Leakage rate <10⁻⁸ Pa·m³/s, resistant to high temperatures and high pressures | Satellite fuel valves, nuclear reactor sensors |

A hermetically sealed connector works by utilizing multiple layers of physical barriers and material properties to create a reliable dielectric isolation barrier while ensuring the proper transmission of power, signals, or fluids. Essentially, it utilizes mechanisms such as elastic deformation, molecular-level bonding, and dynamic compensation at each contact interface and structural gap within the connector to form a continuous series of sealing lines. When the connector is mated, the rubber seal elastically deforms under mechanical pressure, fully filling the annular gap between the metal housing and the cable. The resilient force generated by this compression deformation effectively blocks the macroscopic penetration of moisture and dust. For more stringent sealing requirements, metal is sintered with glass or ceramic at high temperatures to form a dense molecular bond. This porous, fused seal structure can keep leakage rates to extremely low levels and even resist gas diffusion in space environments. For dynamic sealing scenarios requiring relative motion, labyrinth seals significantly increase permeation resistance by designing tortuous gas channels. Magnetic fluid seals use magnetic fields to confine nano-magnetic fluids, forming a fluid, liquid seal between rotating components. The entire sealing system often adopts a multi-protection design, responding to penetration threats of different scales from the outside to the inside. At the same time, it adapts to the sealing challenges brought by temperature and pressure changes by matching the thermal expansion coefficient of the material and optimizing the preload force, ultimately achieving long-term and stable sealing of the connector in complex environments.

2. Key points for selecting and maintaining sealed connectors

The selection and maintenance of sealed connectors directly impact the reliability, lifespan, and safety of your equipment. Understanding selection factors and maintenance recommendations can help ensure stable connector operation in harsh environments.

Selecting the right hermetically sealed connector requires comprehensive consideration of multiple key factors, including the application environment, performance requirements, material compatibility, and long-term reliability. First, the environmental conditions of the specific application scenario must be clearly defined, including temperature range, humidity, pressure, corrosive media, and mechanical vibration. For example, high-temperature and high-pressure chemical environments require corrosion-resistant PTFE seals and stainless steel housings, while deep-sea equipment requires IP68-rated waterproofing and pressure-resistant designs. Secondly, the connector's voltage and current carrying capacity, as well as fluid compatibility, must be determined based on the electrical or fluid transmission requirements. For example, high-voltage systems in electric vehicles require specialized insulation, while medical devices require biocompatible materials. The choice of sealing technology is also crucial. Standard rubber O-rings are suitable for low-cost dust and water resistance, while metal-glass sintering or laser welding are used for aerospace-grade, ultra-high airtightness requirements. The connector's mechanical design is also crucial, including details such as mating life, locking method (for example, threaded locking is more resistant to vibration than snap-on locking), and anti-mismated insertion features. Additionally, consider compliance requirements for industry certifications such as IP protection ratings, ATEX explosion-proof certification, or MIL-STD military standards. When selecting a supplier, balance the high reliability of industrial-grade brands with the cost advantages of consumer-grade products. Customized solutions may be required for specialized operating conditions. Finally, it is recommended to ensure the rationality of the selection through practical verification such as air tightness testing, environmental aging testing, and plug-in life testing. At the same time, establish a maintenance system that regularly checks the condition of the seals, cleans the contacts, and standardizes operation. This ensures that you truly select a sealed connector that meets current needs and withstands long-term testing.

Choosing the right sealing technology:

| Sealing Technology | Advantages | Applications |

| Rubber O-rings | Low cost, easy to replace | Consumer electronics, industrial equipment |

| Metal-glass sintering | Ultra-high airtightness (<10⁻⁸ Pa·m³/s) | Aerospace, vacuum equipment |

| Epoxy resin potting | Completely fills gaps, moisture-proof | Underwater sensors, LED lighting |

| Bellows seals | High-temperature and pressure resistance | Chemical pipelines, high-temperature valves |

Maintenance of sealed connectors is crucial to ensuring long-term reliable operation, focusing on maintaining sealing performance, mechanical structural integrity, and electrical contact stability. Routine maintenance begins with regular inspection of the seals to detect signs of hardening, cracking, or permanent deformation. Especially for connectors used in extreme temperatures or chemically corrosive environments, seal replacement is recommended every 6-12 months. Cleaning and maintenance require specialized tools, such as an alcohol swab to remove contact oxides and a silicone-based grease to maintain the rubber seals (mineral oil-based lubricants are strictly prohibited). Also, carefully inspect the housing threads or snap-on locking mechanism for looseness. The airtightness of critical areas can be quantitatively tested using the pressure decay method or a helium mass spectrometer. Immediate repair is required if the leak rate exceeds the standard value of 10⁻⁵ Pa·m³/s. Regarding operating procedures, vertical insertion and removal must be strictly adhered to to avoid skew wear. Dust caps should be installed when not in use for extended periods, and connectors should be promptly sealed with protective caps after disassembly. Different seal types require differentiated maintenance: Rubber-sealed connectors must be protected from UV aging, metal welded seals must be monitored for thermal fatigue cracking, and potted seals must be monitored for colloid cracking. Establishing a comprehensive maintenance record, documenting each inspection of sealing parameters, replacement parts, and abnormalities, is crucial for predictive maintenance and fault tracing. Through systematic maintenance management, the service life of sealed connectors can be extended by over 30%, reducing the risk of system failures due to seal failure.

Maintenance summary of sealed connectors:

| Maintenance items | Specific operations | Precautions |

| Sealing ring inspection | - Visually inspect for cracks, deformation, and hardening. - Manually test for elastic recovery. | - Replace every 6 months in extreme environments (high temperature/chemical corrosion). - Use sealing rings of the same material when replacing. |

| Contact cleaning | - Wipe the metal contacts with an anhydrous alcohol swab. - Clean stubborn oxide layers with a dedicated conductive paste. | - Do not scrape with a metal brush. - Apply a thin layer of conductive silicone grease after cleaning (use with caution for high-frequency signal connectors). |

| Airtightness testing | - General application: Bubble method (underwater testing). - High precision requirements: Helium mass spectrometer (≤10⁻⁶ Pa·m³/s). | - Test pressure should be 1.5 times the operating pressure. - Maintain a stable test environment temperature. |

| Mechanical structure maintenance | - Check thread/clip tightening force. - Verify the housing is free of cracks and deformation. | - Tighten threads with a torque wrench (refer to manufacturer's standards). Deformed housings must be replaced. |

| Lubrication and Maintenance | - Apply silicone-based grease to the seal groove. - Apply rust inhibitor to metal threads. | - Grease usage should not exceed 30% of the groove volume. - Do not use rust inhibitors containing sulfur or chlorine (they may corrode metals). |

| Storage Management | - Install dust caps for long-term storage. - Maintain ambient humidity <60% and temperature -10-40°C. | - Store seals in a loose state (to avoid prolonged compression). - Power-on test every three months. |

| Operating Specifications | - Maintain axial alignment during insertion and removal. - Unlock components with locking mechanisms. | - Do not insert or remove components while powered on (high-voltage connectors). - Re-tighten components after insertion or removal in vibrating environments. |

| Fault Logs | - Record parameters such as leakage rate and contact resistance for each maintenance session. - Establish a traceability file for replaced parts. |

- Abnormal data should be marked with a red warning. - Report defective components from the same batch to the supplier. |

3. How to Extend the Service Life of Sealed Connectors?

To effectively extend the service life of sealed connectors, comprehensive optimization management is required, from design selection to routine maintenance. By implementing appropriate preventative measures, not only can the service life of sealed connectors be extended by 50%-80%, but the rate of sudden failures can also be reduced by over 90%. The key lies in establishing a refined management system throughout the entire lifecycle to prevent potential failure modes from occurring at the source. For critical equipment, a dual-seal redundancy design is recommended. Even if the primary seal fails, a backup seal can maintain system operation, saving valuable time for repairs.

(1) Scientific selection and design optimization

During the selection stage, a 20%-30% performance margin should be reserved. For example, in a humid environment, an IP protection standard one level higher than the actual demand should be selected.

Match the best sealing material for different working conditions: PTFE or FFKM perfluoroelastomer is used for chemical environments, metal bellows seals are used for high-temperature scenes, and titanium alloy shells are considered for deep-sea applications.

Prioritize models with self-cleaning contacts and foolproof designs to reduce damage caused by human operational errors.

For vibration environments, it is recommended to select products with double locking mechanisms, such as thread + snap-on composite fixing methods.

(2) Standardized installation and operation

Specialized tools must be used during installation. Use tools such as torque wrenches to ensure that the tightening force meets the standard (usually 5-10N·m). The plugging and unplugging operation should follow the "three alignments" principle: axial alignment, angular alignment, and balanced force to avoid uneven wear of the sealing surface caused by oblique insertion. High-voltage connectors must strictly follow the "power off before operation" process to prevent arc erosion of the sealing interface. For multi-core connectors, it is recommended to use a step-by-step plugging and unplugging method, first connect the guide pins and then complete the main body connection.

(3) Systematic maintenance and servicing

Establish a three-tier maintenance system: daily inspection (appearance, insertion and removal force), regular maintenance (quarterly seal lubrication), and annual overhaul (air tightness test).

Use predictive maintenance techniques, such as installing temperature and humidity sensors to monitor environmental changes within the sealed chamber.

Use a dedicated cleaning kit during maintenance, including an anti-static brush, non-woven fabric, and electronic-grade cleaning agent.

Lubricant selection should consider the temperature range: silicone grease is used for low-temperature environments, while perfluoropolyether grease is used for high-temperature environments.

(4) Intelligent status monitoring

Install fiber optic strain sensors on key connectors to monitor pressure changes on the sealing surface in real time. Use acoustic emission technology to detect microscopic leaks, which is 100 times more sensitive than the traditional bubble method. Establish a digital twin model to predict the remaining life of the seal through vibration spectrum analysis. Conduct big data analysis on historical failure data to optimize maintenance cycles and spare parts management. Environmental control and storage management. Long-term storage. Maintain an ideal environment with a relative humidity of 40%-60% and a temperature of 15-25°C. Use a nitrogen-filled storage cabinet to prevent oxidation of metal parts and store rubber parts away from light. Perform power activation every three months to prevent the oxide film on the contact surface from thickening. Establish strict inbound and outbound records to ensure first-in-first-out and avoid inventory aging.

(5) Personnel training and quality management

Operators must pass special certification in sealing technology and master the correct installation techniques. Establish a visual operation guide and use AR technology to assist in the maintenance of complex connectors. Implement a quality traceability system, with each connector having an independent electronic resume file. Conduct regular failure analysis training to improve fault prediction and emergency response capabilities.

Regular maintenance and care:

| Maintenance Items | Operation Guide | Frequency |

| Seal Ring Inspection | Observe for hardening and cracking. Test for elastic recovery by manual pressure. | Every 6-12 months |

| Contact Cleaning | Wipe with an alcohol-based cotton swab. Clean stubborn oxide layers with conductive paste. | Every 3-6 months or if abnormalities occur |

| Lubrication and Maintenance | Apply silicone-based grease to the seal ring groove (≤ 30% of the groove volume). | Every year or after 500 plug-in/plug cycles |

| Airtightness Test | Use the bubble method (IP67 and below) or helium mass spectrometer (high precision required). | Every year or after maintenance. |

| Mechanical Structure Inspection | Confirm that the housing is free of cracks, threads are free of loose threads, and the locking mechanism is functioning properly. | Every 6 months |

Fault warning and replacement strategy:

| Symptoms | Possible Causes | Solutions |

| Increased plugging and unplugging resistance | Dry or contaminated seal | Clean and lubricate or replace seal |

| Poor contact/signal fluctuation | Contact oxidation or seal failure | Clean contacts and check for airtightness |

| Liquid leakage/air leakage from housing | Deteriorated or damaged seal | Replace seal or entire connector |

4. Common Failures and Solutions for Sealed Connectors

Sealed connectors are widely used in industrial, automotive, aerospace, and medical equipment applications. Their core function is to ensure stable electrical connections while protecting against environmental intrusion (such as water, dust, and chemicals). However, in actual use, sealed connectors can still experience various failures due to design, materials, installation, or environmental factors, impacting the proper functioning of equipment. Understanding common sealed connector failures and their solutions, along with preventive maintenance recommendations, can help users improve connector reliability and service life.

One of the most common failures of sealed connectors is seal failure, leading to liquid or gas leakage. Seal failure is typically caused by aging, deformation, or damage to the seal ring, such as hardening, cracking, or permanent deformation of the rubber material after long-term use. Improper installation is also a major culprit, such as improper seal alignment and under- or over-compression, which can compromise the seal. Corrosion on the connector housing or thread wear can also compromise the seal, especially in humid, salt spray, or chemically corrosive environments. Extreme temperature and pressure fluctuations can also cause the seal material to expand or contract, reducing sealing performance. Solutions to this problem include selecting high-performance sealing materials (such as fluoroelastomer, silicone rubber, and other chemically and high-temperature resistant materials), strictly following installation specifications (such as using a torque wrench to ensure uniform compression), and optimizing the sealing structure design (such as using double sealing rings or combining potting compounds for enhanced protection). For corrosive environments, corrosion-resistant housing materials such as stainless steel and nickel-plated alloys should be preferred.

Poor electrical contact is another common fault, manifesting as unstable or complete signal transmission interruption. The electrical performance of sealed connectors can be degraded by water ingress or contaminants (such as salt spray, oil, and dust) at the sealing interface, especially in outdoor or industrial environments. Oxidation or plating wear on pins and sockets can also increase contact resistance, leading to signal attenuation or heat generation. Furthermore, mechanical vibration can cause terminals to loosen, further exacerbating contact problems. To address this issue, select connectors with IP67/IP68 protection ratings to ensure that their sealing performance meets the requirements of the operating environment. Gold or silver plating can significantly improve corrosion resistance and conductivity in terminal design. For high-vibration environments, connectors should be equipped with reliable locking mechanisms, such as thread locks, snap locks, or secondary locking devices, to prevent terminals from loosening.

Mechanical damage can also affect the reliability of sealed connectors. External impact or improper handling can cause cracks in the connector housing, especially in plastic housings. Frequent mating and unmating can accelerate wear of the seals, reducing sealing performance. Threaded sealed connectors can experience thread stripping, seizure, or corrosion, especially in high-humidity or corrosive environments. Solutions to mechanical issues include selecting high-strength materials (such as metal housings or reinforced engineering plastics), limiting mating and unmating cycles (or using more wear-resistant sealing materials such as polyurethane), and applying anti-seize agents (such as molybdenum disulfide grease) to threads to reduce friction and corrosion.

Poor temperature adaptability is another challenge for sealed connectors. In high-temperature environments, sealing materials can soften and lose their elasticity; in low-temperature environments, they can become brittle, leading to seal failure. Furthermore, differences in thermal expansion coefficients between different materials can induce internal stress in the connector, potentially leading to cracking or deformation over time. To improve temperature adaptability, choose sealing materials with a wide temperature range, such as silicone rubber (resistant to temperatures ranging from -60°C to 200°C). In terms of structural design, allowances for thermal expansion can be made, or flexible sealing structures (such as bellows) can be used to absorb thermal stress.

Electromagnetic interference (EMI) is particularly prominent in high-speed signal or highly sensitive devices. The shielding performance of sealed connectors can be reduced by improper sealing design, such as poor grounding of the metal housing or discontinuous shielding layers. To address EMI, conductive sealing rings (such as metal-coated rubber) can be used, or shielding layers can be integrated within the connector to ensure electromagnetic compatibility throughout the transmission path. Furthermore, the connector housing should provide 360° low-impedance contact to optimize shielding effectiveness.

Improper installation and maintenance are also major contributors to sealed connector failures. During installation, unlubricated, reverse-installed, or excessively twisted sealing rings can compromise sealing performance. Using incompatible cleaning agents (such as strong acids, bases, or organic solvents) during maintenance can corrode the sealing material. To avoid these issues, operators should receive professional training and use specialized lubricants (such as silicone grease) to reduce friction and wear. When cleaning connectors, use neutral solvents (such as isopropyl alcohol) and avoid high-pressure washing.

Preventive maintenance is crucial to extending the service life of sealed connectors. Regular inspections are an effective measure, such as using airtightness tests (such as the pressure decay method) to verify sealing performance or measuring contact resistance to assess electrical connection status. In high-humidity or salt spray environments, drainage features or anti-corrosion coatings can be added. For applications with frequent vibration, vibration-resistant locking structures should be preferred, and connector tightening should be regularly inspected. Spare parts management is also crucial. Consumable parts (such as seals and locking mechanisms) should be stocked, and replacement parts should be made of materials consistent with the original design to avoid compatibility issues caused by mixing different batches.

Sealed connector failures are often caused by seal failure, poor electrical contact, mechanical damage, poor temperature adaptability, electromagnetic interference, or improper installation and maintenance. Through reasonable selection, optimized design, standardized installation and regular maintenance, the failure rate can be significantly reduced, ensuring the long-term stable operation of the connector in special environments.

Common fault table of sealed connectors:

| Fault Type | Possible Cause | Impact | Solution |

| Seal Failure | Aging, deformation, or damage of the seal ring; Improper installation; Material incompatibility with the media | Liquid/gas intrusion, resulting in short circuits, corrosion, or performance degradation | Replace the seal ring; Install correctly; Select compatible materials; Regularly inspect the seal |

| Poor contact | Oxidation of contacts; Wear of pins/jacks; Contamination (dust, oil) | Signal interruption, increased resistance, device instability | Clean contacts; Apply anti-oxidation coating; Replace worn parts; Maintain a clean environment |

| Corrosion | Exposure to moisture, salt spray, or chemicals; Seal failure | Rust on metal parts, resulting in reduced conductivity and even short circuits | Select corrosion-resistant materials (such as gold-plated contacts); Strengthen seals; Use protective sleeves or coatings |

| Mechanical damage | Excessive insertion and removal force; Loosening due to vibration/shock; Cracked housing | Connector breakage, poor contact, or complete failure | Regulate operating force; Reinforce the installation; Use vibration-resistant design; Avoid external shock |

| Degraded insulation performance | Aging insulation materials; moisture or contamination; degradation due to high temperatures | Increased risk of leakage and short circuits | Replace insulation materials; keep dry and clean; choose high-temperature-resistant materials (such as silicone or Teflon) |

| Excessive temperature | Overcurrent; high ambient temperature; high contact resistance | Accelerated aging, or even melting of the insulation | Optimize heat dissipation design; reduce current load; choose high-temperature materials; monitor operating temperature |

| Pin/socket misalignment | Assembly errors; deformation due to mechanical stress | Improper connection; insufficient contact pressure | Recalibrate; use guides; avoid deformation due to external forces |

| Chemical corrosion | Exposure to acids, alkalis, solvents, etc. | Dissolution or embrittlement of housing or sealing materials | Select chemical-resistant materials (such as fluoroelastomer); avoid contact with harmful media |

| Electromagnetic interference (EMI) | Shield damage; poor grounding | Signal noise or transmission errors | Check shield integrity; ensure good grounding; select connectors with EMI protection |

| Material aging | Extended exposure to UV rays, ozone, or extreme temperatures | Degraded sealing/insulation properties and reduced mechanical strength | Replace regularly; select aging-resistant materials (such as EPDM rubber); avoid exposure to harsh environments |

Additional Notes:

Preventive Maintenance: Regularly check seals, contact condition, and insulation resistance, especially in harsh environments.

Selection Recommendations: Choose a connector with an IP rating (such as IP67/IP68 waterproof), temperature resistance, and corrosion resistance based on the application scenario.

Testing Standards: Air tightness testing, high-voltage insulation testing, and vibration testing can detect potential faults in advance.

5.Sealed Connector Frequently Asked Questions (FAQ)

(1). What is a sealed connector?

A sealed connector is an electrical connector with waterproof, dustproof, and gas-proof properties, and is usually used in harsh environments (such as outdoors, automobiles, industry, ships, etc.). Its sealing performance is usually expressed in IP (Ingress Protection) levels, such as IP67 (dustproof and waterproof) or IP69K (high-voltage and high-temperature waterproof).

(2). What are the main application scenarios of sealed connectors?

Automotive industry: engine compartment, vehicle electronics, charging interface

Industrial equipment: automated machinery, sensors, control cabinets

Outdoor electronics: LED lighting, surveillance cameras, solar equipment

Marine/aviation: electrical connections in humid and salt spray environments

Medical equipment: occasions that require protection against liquid intrusion

(3). How to determine whether a sealed connector has failed?

Physical inspection: whether the sealing ring is damaged, deformed, or aged

Electrical test: increased contact resistance, decreased insulation resistance

Functional abnormality: unstable signal, equipment short circuit or open circuit

Environmental test: airtightness test (such as air pressure detection)

(4). What are the sealing ring materials for sealed connectors? How to choose?

Common materials:

Silicone rubber (VMQ): High temperature resistant (-60°C ~ 200°C), suitable for automobiles and industry

Fluororubber (FKM): Oil resistant and chemical resistant, suitable for chemical industry and shipbuilding

EPDM rubber: Ozone resistant and aging resistant, suitable for outdoor equipment

NBR (nitrile rubber): Low cost, suitable for general dust and water proofing

Selection basis: ambient temperature, chemical medium, mechanical strength requirements.

(5). Will the sealed connector fail in a high temperature environment?

Possibly, the reasons include:

Aging of the sealing ring (silicone can withstand high temperatures, but long-term high temperatures will still accelerate aging)

Deformation of the plastic shell (select high temperature resistant materials such as PPS, PA66)

Oxidation of metal contacts (gold-plated or silver-plated contacts are more resistant to high temperatures)

Solution: Select high temperature resistant materials (such as FKM rubber, metal shell), and optimize the heat dissipation design.

(6). How to properly install the sealed connector to ensure sealing?

Check the sealing ring: make sure it is not damaged and is properly installed. Tighten it according to the specifications: avoid over-tightening (causing deformation) or over-loosening (causing leakage). Use lubricants (such as silicone grease) to reduce friction and extend the life of the sealing ring. Avoid twisting the cable to prevent stress damage to the sealing structure.

(7). Are sealed connectors corrosion-resistant?

Depends on the material: Housing: stainless steel, engineering plastics (such as PA66) corrosion-resistant Contacts: gold plating, nickel plating to prevent oxidation Seal: fluororubber (FKM) acid, alkali, and oil resistance Enhanced anti-corrosion measures: Select IP68 or higher protection level Use anti-corrosion coating Clean regularly to avoid salt spray and chemical accumulation

(8). Are sealed connectors easy to loosen in a vibrating environment?

It may loosen, resulting in: Poor contact (unstable signal) Seal failure (liquid/dust intrusion) Anti-vibration design: Use locking mechanisms (such as threads, snaps) Select anti-vibration sockets (such as spring pin design) Reinforce the cable to avoid vibration transmission

(9). How to clean and maintain sealed connectors?

Clean contacts: Use anhydrous alcohol or electronic cleaner

Check seals: Regularly replace aged or deformed seals

Avoid direct impact with high-pressure water jets (unless IP69K compatible)

Storage: Store in a dry environment, avoid long-term exposure to UV rays

(10). Can the sealed connector be repaired?

Repairable: Replace the seal, clean the contacts, and re-tighten

Unrepairable: Cracked housing, damaged internal circuits

Recommendation: Replace directly if severely damaged to avoid safety hazards

6.Several key indicators: teach you to choose the right sealed connector

In areas such as industrial automation, new energy vehicles, and outdoor electronic equipment, the choice of sealed connectors directly impacts the reliability and lifespan of the equipment. A wrong choice can lead to waterproofing failure, signal interruption, and even safety hazards. Faced with a wide variety of products on the market, how can one quickly identify the most suitable sealed connector? The key lies in understanding five core indicators: protection rating, material properties, electrical performance, mechanical strength, and environmental adaptability. Choosing the right sealed connector not only reduces maintenance costs but also ensures long-term stable operation of the equipment.

First, the protection rating is the first criterion for sealed connectors. IP67 represents dustproof and temporary waterproofing, suitable for most outdoor equipment; IP68 can withstand long-term underwater operation and is commonly used in deepwater exploration or underground engineering; and IP69K can withstand high-pressure, high-temperature water washdowns and is the preferred choice for food processing and chemical equipment. If the application involves salt spray or corrosive gases, additional attention should be paid to the material's chemical resistance.

The choice of material directly determines the lifespan of the connector. Engineering plastics (such as PA66) for the housing offer both lightweight and corrosion resistance, while metal housings (such as stainless steel) are more suitable for shock and high-temperature environments. The material of the sealing ring is also critical: Silicone rubber is heat-resistant and suitable for automotive electronics in the engine compartment; Fluorocarbon rubber is oil-resistant and chemical-resistant, making it an ideal choice for chemical equipment; and EPDM rubber, with its excellent aging resistance, is a standard for outdoor lighting.

Electrical performance ensures stable signal transmission. The rated current and voltage must match the equipment requirements to avoid overheating due to overload. Contact resistance should be as low as possible (typically <10mΩ). Especially for high-frequency signal transmission, gold- or silver-plated contacts can significantly improve reliability. Insulation resistance should be above 100MΩ to prevent leakage risks. Connectors with EMI shielding are essential for sensitive signals in in-vehicle communications or industrial automation.

Mechanical strength determines the durability of a connector in harsh environments. The number of plug-in and unplug cycles is a key indicator, with industrial-grade connectors typically requiring more than 5,000 plug-in and unplug cycles without failure. In environments with high vibration (such as automotive and aviation), threaded locking designs are more reliable than standard snap-on designs. Furthermore, the cable fixing method should be considered to prevent internal solder joints from breaking due to long-term vibration.

Finally, environmental adaptability is a comprehensive consideration in product selection. Wide-temperature connectors (-40°C to 125°C) are suitable for extremely cold or high-temperature environments. Outdoor environments with strong UV rays require UV-resistant materials (such as black PBT housings). In chemical plants or coastal areas, corrosion-resistant stainless steel housings paired with fluororubber seals can effectively extend service life.

When selecting a connector, it is recommended to cross-reference these five key indicators based on the specific application scenario. For example, high-voltage systems in new energy vehicles require IP67/IP69K protection, silicone seals, gold-plated contacts, and vibration-resistant designs; while marine equipment prioritizes salt-spray-resistant stainless steel housings and fluororubber seals. Consulting manufacturer data sheets and sample testing (e.g., airtightness and high- and low-temperature cycling) are key steps in verifying performance.

Five key indicators for selecting sealed connectors

(1) Protection level (IP code)

Key question: Does it need to be dustproof, waterproof or chemically resistant?

IP67: Dustproof + short-term immersion in water (1 meter depth, 30 minutes)

IP68: Long-term waterproof (depth and time defined by the manufacturer)

IP69K: High-pressure, high-temperature water wash-off (suitable for food and chemical equipment)

Special protection: such as salt spray (ships), oil (industrial machinery)

Selection recommendation: Outdoor equipment must be at least IP67, and IP68/IP69K for harsh environments.

(2) Material selection

1) Housing material Engineering plastics (PA66, PPS): lightweight, corrosion-resistant, suitable for general industry Metals (stainless steel, aluminum alloy): impact-resistant, high-temperature resistant, suitable for automobiles and aviation.

2) Sealing ring material Silicone rubber (VMQ): high-temperature resistant (-60°C~200°C), suitable for automotive electronics Fluororubber (FKM): oil-resistant and chemical-resistant, suitable for chemical and marine applications EPDM rubber: ozone-resistant, suitable for long-term outdoor use Selection recommendations: Choose silicone for high-temperature environments and fluororubber for chemical-corrosive environments.

(3). Electrical performance

Key parameters:

Rated current/voltage: avoid overload and heat generation (e.g. automotive high-voltage connectors must support 12V/24V or higher)

Contact resistance: low resistance (<10mΩ) to ensure signal stability

Insulation resistance: >100MΩ (anti-leakage)

Shielding performance: Connectors with EMI shielding are suitable for high-frequency signals (e.g. in-vehicle communications)

Selection recommendations: select gold/silver-plated contacts for high-current scenarios, and shielding design is required for precision signal transmission.

(4). Mechanical strength

Key indicators:

Plug-in life: Industrial-grade connectors usually require more than 5,000 plug-in/out cycles

Vibration/shock resistance: automotive and aviation applications must comply with relevant standards (e.g. ISO 16750)

Locking method: threaded (high reliability), snap-on (quick installation)

Selection recommendations: select threaded locking for vibration environments, and select high-life models for frequent plug-in/out.

(5). Environmental Adaptability

Environmental Factors to Consider:

Temperature Range: Industrial Grade (-40°C to 125°C), Automotive Grade (-40°C to 150°C)

Chemical Resistance: Choose fluororubber or specialty plastics for contact with oils, acids, and alkalis.

UV Resistance: For long-term outdoor exposure, choose UV-resistant materials (such as black PBT housing).

Selection Recommendations: Choose wide-temperature materials for extreme temperature environments and corrosion-resistant coatings for chemical environments.

Request for a call today

English

English русский

русский