What are some common malfunctions of RF connectors?

2025.12.09

2025.12.09

Industry News

Industry News

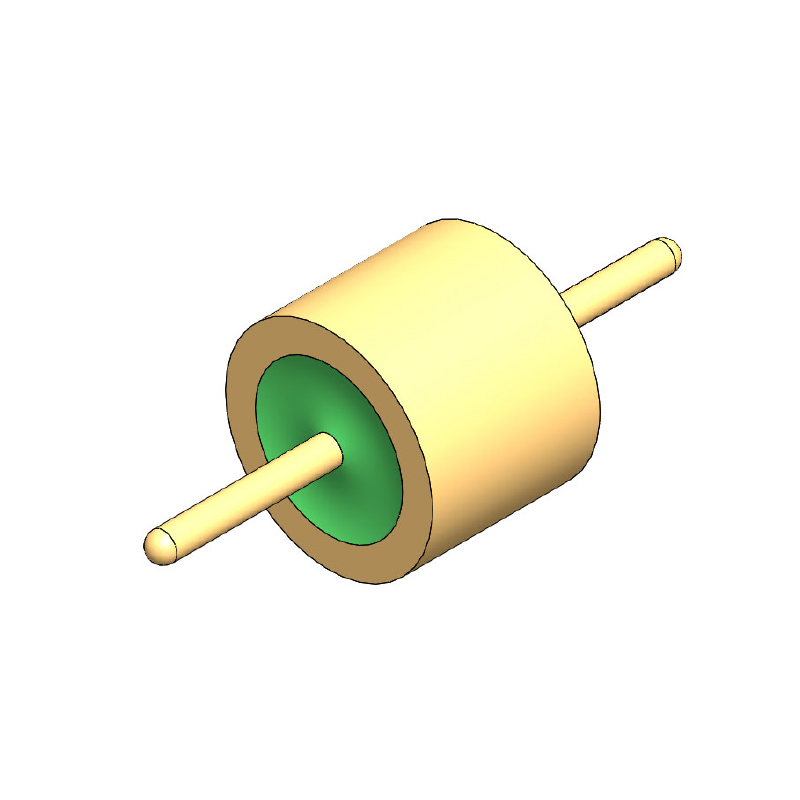

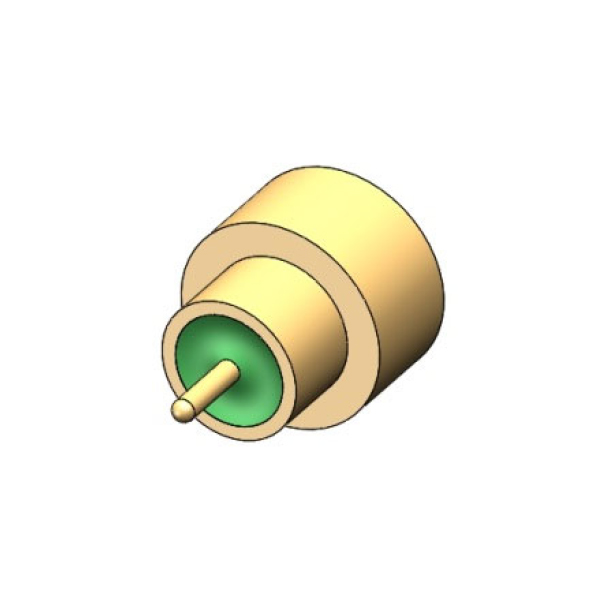

Radio frequency (RF) connectors play a crucial role in modern communication and electronic equipment, especially in high-frequency signal transmission. Whether in wireless communication, 5G networks, satellite communication, or applications such as broadcasting, television, and radar systems, RF connectors must ensure signal stability and integrity. However, in practical applications, RF connectors can experience various faults that affect the normal operation of the equipment.

1. Common RF Connector Faults

(1) Signal Attenuation

Fault phenomenon: Signal attenuation usually manifests as a decrease or complete loss of signal strength, leading to degraded communication quality, such as unclear sound or video stuttering.

Causes:

Damaged or aged connector, resulting in poor contact.

The connector material or design is unsuitable for the transmission frequency range.

Inappropriate signal cable or the use of low-quality connecting cables.

(2) Poor Contact

Fault phenomenon: Poor contact usually leads to unstable signal transmission, frequent disconnections, or no signal.

Causes:

Incomplete contact between the connector plug and socket.

Damaged pins on the plug or socket, preventing a good electrical connection with the other end.

Loose or incompletely locked threads.

(3) High-Frequency Signal Reflection

Fault phenomenon: Signal reflection can cause signal transmission distortion, manifesting as frequent interference, noise, or echo problems, affecting equipment performance.

Causes:

Poor impedance matching of the connector, failing to match the impedance of the cable or other connecting components.

Unreasonable connector design, leading to reflection during signal transmission.

Loose connections or air gaps at the joint, causing signal attenuation and reflection.

(4) Electrical Short Circuit or Open Circuit

Fault phenomenon: Electrical short circuits can cause current overload, damaging the circuit and even leading to equipment failure. Open circuits will result in a complete inability to transmit signals.

Causes:

Damage to internal metal components of the connector, interrupting the conductive path.

Broken connector pins or poor solder joints.

Improper installation or strong vibration causing movement of internal connector components.

(5) Damage Caused by Environmental Factors

Fault phenomenon: In outdoor or special environments, connectors may be affected by weather, moisture, or corrosive substances, leading to performance degradation or complete failure. Reasons:

Prolonged exposure to harsh environments can cause oxidation, corrosion, or salt spray erosion of the connector.

High temperatures, low temperatures, or humid conditions can affect the connector's sealing performance.

2. Methods to Solve RF Connector Failures

(1) Troubleshooting Signal Attenuation Problems

Solutions:

Check connector quality: Regularly check connectors for aging or damage, especially in high-frequency signal transmission applications. Aging connectors can lead to signal loss or attenuation.

Use high-quality connectors: Ensure that the RF connectors used are designed for the frequency range of the current system, and use materials with good transmission characteristics, such as metal plating and highly conductive materials.

Check cable matching: Ensure that the impedance of the connector and cable are matched. Common impedance standards are 50Ω and 75Ω. Choose the appropriate cable and connector combination.

(2) Improving Poor Contact

Solutions:

Re-insert the connector: Ensure complete contact between the connector plug and socket. Gently rotate the plug to ensure it is fully inserted.

Check connector pins: Regularly check the metal pins of the connector for wear, bending, or damage. If problems are found, replace or repair them promptly.

Tighten screws: For threaded RF connectors, ensure that the nuts and threaded parts are tightened to prevent poor contact due to looseness.

(3) Solving High-Frequency Signal Reflection

Solutions:

Check impedance matching: Ensure that the impedance of the RF connector, coaxial cable, and other components are consistent. Impedance mismatch can lead to signal reflection and increased signal distortion.

Use appropriate connectors and accessories: Choose connectors that match the impedance of the cable and equipment, avoiding the use of components with different impedances.

Ensure tight connections: Check that the connectors are in full contact and not loose, avoiding air gaps that can cause reflection.

(4) Solving Electrical Short Circuits or Open Circuits

Solutions:

Check the inside of the connector: If an electrical short circuit or open circuit occurs, check the inside of the connector for obvious damage, such as broken pins, short circuits, or looseness.

Replace damaged connectors: For short circuit or open circuit faults that cannot be repaired, replace the damaged RF connector promptly.

Pay attention to correct installation: Ensure that the correct operating procedures are followed during installation to avoid damage caused by improper operation.

(5) Protecting connectors from environmental damage

Solutions:

Choose waterproof and corrosion-resistant connectors: If the connector needs to be used outdoors or in harsh environments, choose connectors with waterproof, dustproof, and corrosion-resistant features, such as those with IP67 or IP68 protection ratings.

Use sealant: Apply appropriate sealant to the connector interface to prevent moisture, rain, or salt spray from entering.

Regular cleaning and inspection: During use, regularly clean the connector and cable interface to ensure there is no accumulation of dirt, oil, or salt.

Request for a call today

English

English русский

русский