Are Hermetically Sealed Connectors the Best Solution for Harsh Environments?

2026.02.06

2026.02.06

Industry News

Industry News

Yes—hermetically sealed connectors are the most reliable choice for applications exposed to moisture, gas, pressure, and extreme temperatures. By creating an airtight and leak-proof barrier, they significantly reduce signal failure, corrosion, and system downtime. Below, we explore how they work, where they perform best, and how to choose the right type for your project.

Content

- 1 What Makes a Connector “Hermetically Sealed”?

- 2 Why Are Hermetically Sealed Connectors Critical in Industrial Applications?

- 3 Which Industries Benefit Most from Hermetically Sealed Connectors?

- 4 How Do You Choose the Right Hermetically Sealed Connector?

- 5 FAQ: Common Questions About Hermetically Sealed Connectors

What Makes a Connector “Hermetically Sealed”?

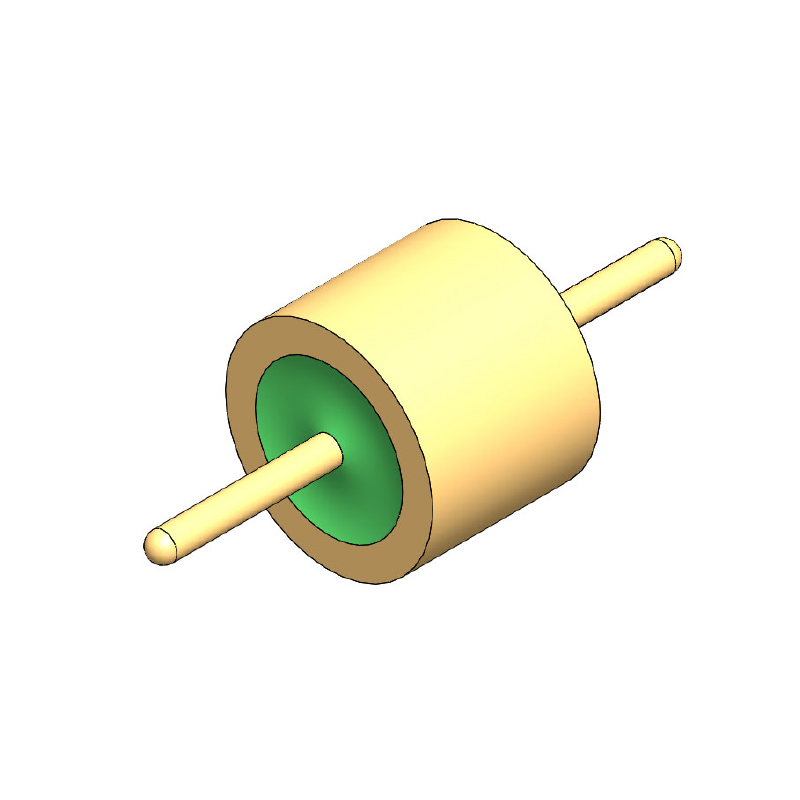

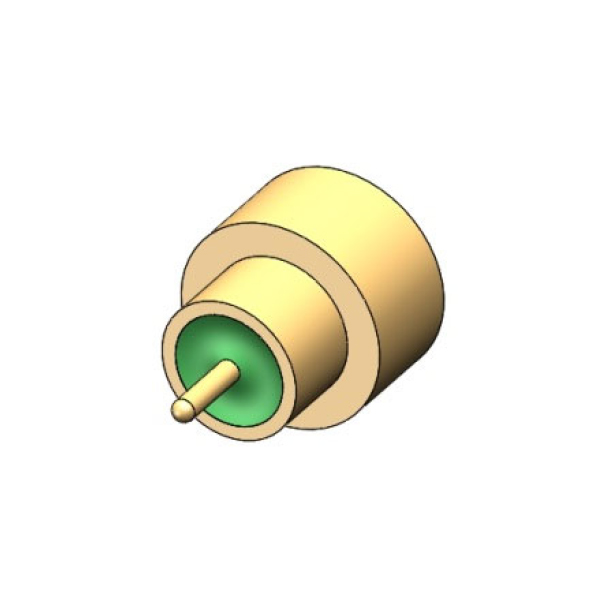

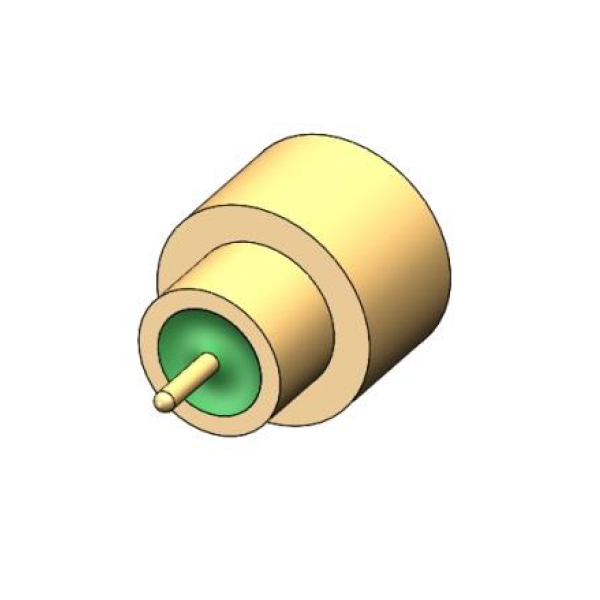

A hermetically sealed connector uses glass-to-metal or ceramic-to-metal sealing technology to prevent the passage of air, water vapor, or gas. This design ensures long-term stability even in vacuum or high-pressure environments.

- Leak rates as low as 1×10⁻⁹ atm·cc/sec

- Operating temperatures up to +300°C

- High resistance to corrosion and oxidation

Why Are Hermetically Sealed Connectors Critical in Industrial Applications?

In critical systems, even minor leakage can cause signal loss or equipment failure. Hermetically sealed connectors provide stable electrical performance and mechanical strength, making them ideal for high-risk environments.

| Feature | Standard Connector | Hermetically Sealed Connector |

|---|---|---|

| Moisture Resistance | Medium | Excellent |

| Leak Protection | Limited | Near Zero Leakage |

| Service Life | 3–5 Years | 10+ Years |

Which Industries Benefit Most from Hermetically Sealed Connectors?

Hermetically sealed connectors are widely adopted in sectors where safety and reliability are critical.

- Aerospace and aviation control systems

- Medical imaging and diagnostic equipment

- Oil and gas exploration tools

- Defense and communication devices

For example, in subsea equipment, hermetically sealed connectors can withstand pressures exceeding 10,000 PSI while maintaining stable signal transmission.

How Do You Choose the Right Hermetically Sealed Connector?

Selecting the correct connector depends on environmental conditions, electrical requirements, and mechanical constraints.

- Confirm operating temperature and pressure limits

- Match voltage and current ratings

- Choose appropriate sealing materials (glass or ceramic)

- Verify compliance with industry standards

FAQ: Common Questions About Hermetically Sealed Connectors

Are hermetically sealed connectors waterproof?

Yes. They are not only waterproof but also resistant to gas and vapor penetration, providing complete environmental isolation.

Do they require special maintenance?

Minimal maintenance is required. Periodic visual inspection and electrical testing are usually sufficient.

Are hermetically sealed connectors more expensive?

Initial costs are higher, but their long service life and reduced failure rate often result in lower total ownership cost over time.

Request for a call today

English

English русский

русский