-

Proper Installation of a Coaxial Connector Ensures Maximum Signal Performance Installing a Coaxial Connector correctly prevents signal loss, interference, and connection failure. A poorly installed connector can reduce signal strength by 20–50%, cause intermittent connectivity, and even damage connected equipment. By ...

READ MORE -

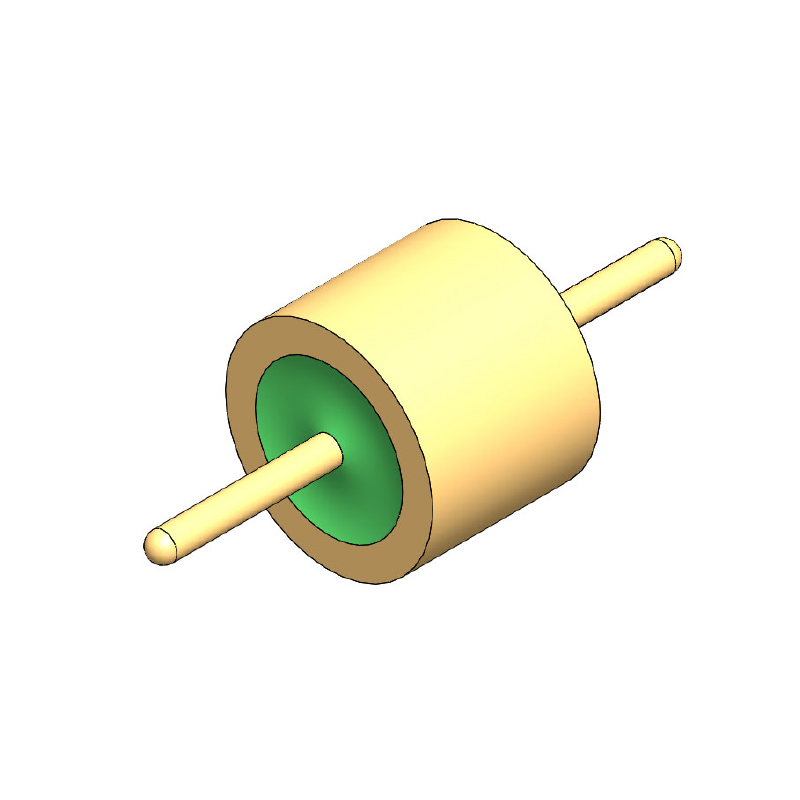

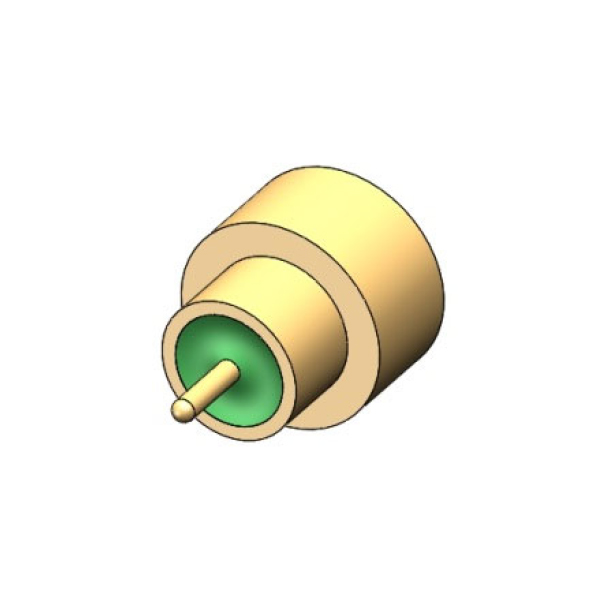

What is an RF Coaxial Connector and Why is it Important? An RF coaxial connector is a crucial component used to transmit radio frequency (RF) signals between devices. These connectors ensure reliable and secure connections for high-frequency signals, which are essential in telecommunications, broadcasting, and network...

READ MORE -

What Are Hermetically Sealed Connectors? Hermetically sealed connectors are specialized connectors that are designed to protect sensitive electronic components from environmental elements like moisture, dust, and corrosive gases. The term "hermetically sealed" refers to the connector’s ability to create an airtight se...

READ MORE

RF coaxial connectors are key nodes in high-frequency signal transmission, and their installation quality directly impacts the performance of the entire communication system. They are typically used to connect two different interface types, ensuring signal transmission between connectors of different standards or sizes. RF coaxial adapters primarily serve to change connection methods, convert interface types, or adapt to devices with different frequency and impedance requirements. Ningbo Hansen Communication Technology Co., Ltd. is a manufacturer specializing in the production, processing, and trading of communications components, with over 30 years of experience in RF coaxial connectors, adapters, and cable assemblies. The company has developed its own machining, electroplating, and assembly shops, along with a stable and reliable network of suppliers.

1. Pre-Installation Preparations

Environmental Control Requirements:

The installation environment should maintain a stable temperature of 15-30°C and a relative humidity of ≤60%. The work area cleanliness level must meet ISO Class 6 standards. The work surface must meet anti-static requirements, with a surface resistivity within the range of 1×10⁴-1×10⁶Ω.

Tools and Testing Equipment:

High-precision torque wrench (±0.1 N·m)

End-face inspection microscope (magnification ≥40X)

Network analyzer (frequency range covers the test band)

Professional cleaning kit (includes anhydrous ethanol, dust-free cloth, etc.)

Connector Quality Inspection: Use optical inspection equipment to inspect the connector end face to ensure scratch depth is ≤0.05mm and that there are no visible surface contaminants. Contact resistance should be ≤1mΩ, and impedance matching tolerance should be within ±1Ω.

2. RF Coaxial Adapter Maintenance Guide

Cleaning and Maintenance

Clean the connector monthly with anhydrous ethanol (purity ≥99.7%) and a dust-free cloth. Treat stubborn stains with a dedicated RF connector cleaner. Maintain a single-direction wipe when cleaning (do not wipe in a rotating motion).

Contact Inspection

Check the elastic recovery of the center pin weekly. Observe contact surface wear using a 10x magnifying glass. Measure contact resistance (should be ≤2mΩ).

Protective Measures

Install a dust cap (IP54 rating) when not in use for extended periods.

Store in an ambient humidity ≤60% RH. Avoid storage with organic solvents.

Request for a call today

English

English русский

русский